Waterborne paint systems, popular in automotive repairs, use water as a solvent instead of organic chemicals, offering environmental and user safety benefits. These systems include pigment particles, binders, thickeners, and specialty ingredients for smooth finishes and superior color retention. Key advantages include faster drying times and enhanced weather resistance, making them valuable for both professional and DIY car paint jobs. The unique drying process involves controlled water evaporation to prevent paint defects, ensuring durable results in collision repair while improving indoor air quality. Understanding temperature, humidity, and airflow is crucial for achieving flawless finishes.

In the realm of coatings, waterborne paint systems have emerged as a sustainable alternative. This article delves into the intricate drying process that sets these systems apart. From understanding the unique composition of waterborne paints to exploring their advanced drying mechanisms, we uncover the science behind their rapid and high-quality performance. Several factors, such as temperature, humidity, and film thickness, significantly influence drying times, ensuring optimal results in various applications.

- Understanding Waterborne Paint Composition

- Drying Mechanisms in Waterborne Systems

- Factors Influencing Drying Times and Quality

Understanding Waterborne Paint Composition

Waterborne paint systems have gained significant popularity in various industries, including automotive repairs. Understanding their composition is key to appreciating their unique properties and benefits. These paints are designed with a base of water as the primary solvent, instead of traditional organic solvents like acetone or toluene. This not only makes them more environmentally friendly but also safer for users, especially in enclosed spaces like auto repair shops. The formula typically includes pigment particles suspended in water, along with various additives that enhance performance.

Key components can include binders, which hold the pigment together and adhere it to the surface, as well as thickeners that control paint viscosity, and other specialty ingredients that offer benefits such as improved flow, faster drying times, and better resistance to weathering. In automotive repair, these systems are highly valued for their ability to produce smooth finishes and superior color retention, making them a go-to choice for both professional and DIY car paint repairs.

Drying Mechanisms in Waterborne Systems

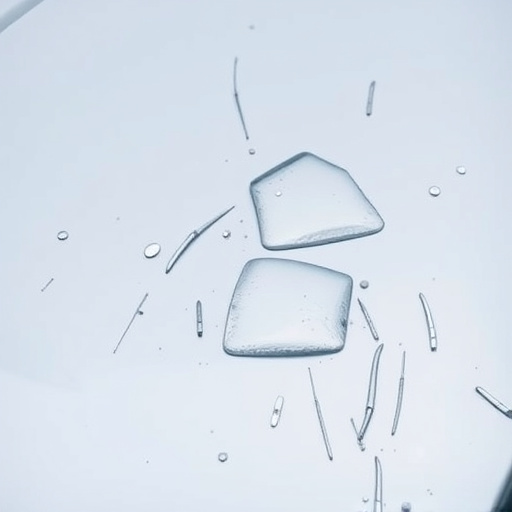

Waterborne paint systems offer a unique drying process compared to traditional solvent-based paints, which has significant implications for industries like automotive repair services and vehicle bodywork. The key difference lies in the mechanisms that enable the paint to dry. In waterborne systems, water acts as the primary solvent, evaporating over time to leave behind a solid polymer film. This process is facilitated by various factors, including the type of resin used, the addition of surfactants, and environmental conditions like temperature and humidity. Unlike solvent-based paints where volatile organic compounds (VOCs) contribute to faster drying times, waterborne systems rely on the natural evaporation of water, making them more environmentally friendly.

The slow yet consistent evaporation of water allows for a more controlled drying process in vehicle bodywork applications, such as car collision repair. This control is beneficial as it minimizes the risk of paint cracking or bubbling, ensuring a smoother and more durable finish. Moreover, the absence of harmful VOCs makes waterborne paints a safer option for workers in automotive repair services, contributing to improved indoor air quality.

Factors Influencing Drying Times and Quality

The drying process of waterborne paint systems is a complex interplay between several factors. Key influences include temperature, humidity, and airflow, which collectively determine the time it takes for the paint to cure and achieve optimal quality. Higher temperatures accelerate drying, while lower humidity levels facilitate faster evaporation of moisture. Adequate airflow ensures even drying across all surfaces, minimizing the risk of orange peel or other defects.

In a collision repair shop or during bumper repair, understanding these factors is crucial for achieving professional results with waterborne paint systems. For instance, technicians may need to adjust drying times or use specialized equipment like heat lamps or ventilation systems to manage humidity and airflow, ensuring that cars leave the shop with flawless finishes—a far cry from unsightly dings and dents left untreated through improper car dent removal techniques.

Waterborne paint systems offer a superior drying experience compared to traditional options, thanks to their advanced composition and innovative drying mechanisms. By understanding the intricate details of these systems—from their unique chemical makeup to the factors affecting drying times—professionals can ensure optimal performance and quality. This knowledge is essential for achieving fast drying times, enhanced durability, and an aesthetically pleasing finish in various applications, solidifying waterborne paint systems as a reliable and efficient choice in the industry.