Data-driven repair planning transforms automotive workshops by using historical data and trends to optimize car damage and collision repairs. It empowers technicians to identify recurring issues, enhance inventory management, predict service demands, and make informed decisions in real-time. This method improves efficiency, reduces errors, expedites turnaround times, boosts productivity, and increases customer satisfaction in the competitive auto repair market. Additionally, it saves costs through optimized parts inventory, effective labor allocation, and streamlined processes.

In today’s digital age, auto technicians can transform their workshops with data-driven repair planning. This innovative approach leverages the power of information to enhance efficiency across all aspects of automotive servicing. By analyzing historical data, identifying trends, and streamlining processes, technicians can achieve accurate diagnoses faster, optimize parts inventory, and reduce labor costs. Discover how embracing a data-centric mindset revolutionizes the auto industry, ensuring better outcomes for both businesses and their clients.

- Enhancing Efficiency: Streamlining Repair Processes

- Accurate Diagnosis: Leveraging Data for Effective Solutions

- Cost Savings: Optimizing Parts Inventory and Labor

Enhancing Efficiency: Streamlining Repair Processes

Implementing data-driven repair planning significantly enhances efficiency within automotive workshops. By analyzing historical data and trends, technicians can streamline their processes for car damage repair and collision damage repair. This approach enables them to identify common issues, optimize inventory management, and predict service demands, ensuring a smoother workflow.

With access to real-time information, auto technicians can make informed decisions, reducing time wasted on unnecessary tasks. Streamlined procedures lead to faster turnaround times, improved productivity, and higher customer satisfaction, making data-driven repair planning an invaluable asset in the competitive automotive repair industry.

Accurate Diagnosis: Leveraging Data for Effective Solutions

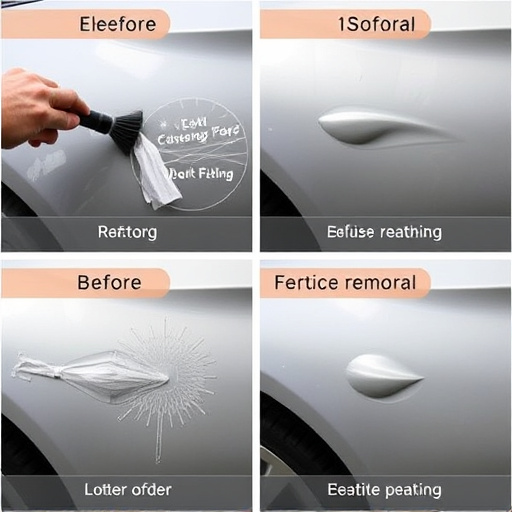

In the fast-paced world of automotive service, accurate diagnosis is key to efficient and effective auto technician workflows. Traditional methods often rely on experience and guesswork, leading to potential errors and misdiagnoses. However, with data-driven repair planning, technicians can leverage a wealth of information to pinpoint issues with precision. By analyzing historical data, service records, and real-time sensor readings, patterns emerge that reveal the root causes of problems. This, in turn, enables auto body repair professionals to prescribe tailored solutions for various automotive body work needs, from minor fixes like car dent removal to more complex repairs.

Data-driven approaches empower technicians with actionable insights, ensuring they select the optimal tools and parts for each unique scenario. This not only enhances service quality but also streamlines processes, reducing the time spent on diagnostics and increasing overall productivity. Ultimately, it translates into better customer satisfaction, as issues are resolved swiftly and accurately, fostering trust in the services provided.

Cost Savings: Optimizing Parts Inventory and Labor

Implementing data-driven repair planning offers significant cost savings for auto technicians and their workshops. By leveraging historical data and real-time insights, technicians can optimize parts inventory management. This approach ensures that commonly required parts are always in stock, reducing costly delays caused by backorders. Moreover, efficient inventory management minimizes waste and overstocking, freeing up valuable storage space.

In the realm of labor optimization, data-driven planning enables technicians to allocate resources more effectively. Analyzing past repair tasks helps identify common procedures and parts replacements, allowing for standardized work processes. This standardization streamlines repairs, reducing the time spent on each job. As a result, car restoration and collision damage repair processes become more efficient, leading to improved productivity and reduced labor costs for the body shop.

Data-driven repair planning offers auto technicians a powerful toolkit to enhance efficiency, ensure accurate diagnoses, and realize significant cost savings. By leveraging insights from historical data, technicians can streamline repair processes, optimize parts inventory management, and allocate labor resources more effectively. This approach not only improves workshop productivity but also contributes to increased customer satisfaction through faster turnaround times and reduced expenses. Embracing data-driven repair planning is a strategic move for auto repair businesses aiming to stay competitive in today’s market.