Electronic measuring equipment like voltmeters, ammeters, and multimeters are vital for accurate measurements in various industries, from automotive repair to advanced manufacturing. Their versatility enables precise assessments of voltage, current, and resistance, ensuring quality globally. Regular calibration and maintenance, including cleaning and storage, extend lifespan and reliability. The demand for precision drives their use across sectors, with the automotive industry heavily reliant on them for tasks like dent removal, auto glass replacement, and detailed bodywork measurements, fostering efficiency and excellence.

Unraveling the intricacies of electronic measuring equipment is essential for professionals across diverse industries. From precise data collection to quality control, these devices play a pivotal role in modern work processes. This comprehensive guide explores various types, their functions, and essential calibration techniques. We delve into common applications, showcasing the versatility of such equipment. By understanding these fundamentals, users can ensure accurate measurements, optimize performance, and stay ahead in today’s tech-driven landscape.

- Types of Electronic Measuring Equipment and Their Functions

- Basic Calibration and Maintenance Techniques

- Common Applications Across Industries

Types of Electronic Measuring Equipment and Their Functions

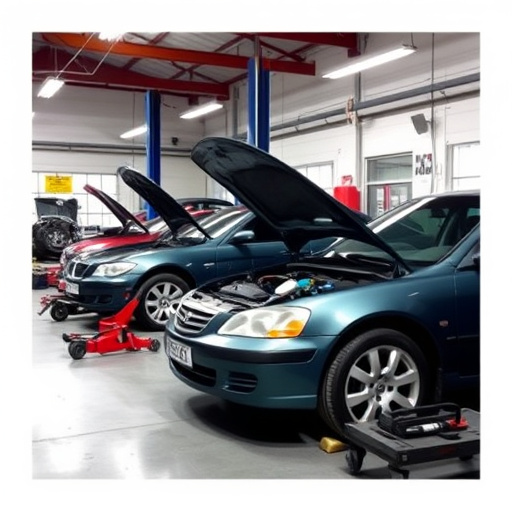

The world of electronic measuring equipment offers a diverse array of tools designed to accurately assess various physical quantities. Among the most common types are voltmeters, used to measure electrical voltage; ammeters for current measurement; and ohmmeters to determine resistance. These devices play a crucial role in fields such as automotive repair, particularly in vehicle body shops where precise measurements ensure accurate luxury vehicle repair and car body repair.

Other specialized equipment includes multimeters, versatile tools capable of measuring multiple parameters like voltage, current, and resistance, making them indispensable for complex tasks. In industries requiring meticulous precision, such as advanced manufacturing or electronics assembly, these instruments are essential. Their functionality spans from simple troubleshooting to intricate design verification, underscoring their significance in modern workshops and engineering practices.

Basic Calibration and Maintenance Techniques

Maintaining and calibrating electronic measuring equipment is an essential aspect of ensuring precision and accuracy in various industries. Regular calibration involves comparing the readings of your tools against known standards to ensure they are functioning within acceptable limits. This process allows for any adjustments or replacements needed to be made, thus maintaining the integrity of measurements taken with electronic measuring equipment.

For instance, in vehicle repair services, precise measurements are crucial when it comes to dent removal and auto glass replacement. Calibrated tools ensure that dimensions are accurate, minimizing errors during these processes. Proper maintenance routines should also include regular cleaning, inspection for wear and tear, and keeping the equipment in a controlled environment to prevent damage from extreme temperatures or humidity, all of which contribute to extending the lifespan and reliability of electronic measuring equipment.

Common Applications Across Industries

In various industries, the demand for precision and accuracy drives the utilisation of electronic measuring equipment. From manufacturing and construction to automotive sectors, these tools play a pivotal role in ensuring quality and safety standards. In car paint services, for instance, electronic measuring equipment is used to gauge the thickness of paint applications, thereby maintaining consistent and high-quality finishes. Similarly, in frame straightening operations, accurate measurements are crucial to restore vehicles’ structural integrity after collisions or accidents.

In vehicle bodywork, these devices enable meticulous assessments of panel gaps, angle measurements, and curve detection, ensuring seamless and flawless repairs. The automotive industry’s reliance on electronic measuring equipment underscores its significance across diverse sectors. This technology’s ability to provide rapid, reliable, and detailed data makes it indispensable in modern workshops and production lines, fostering efficiency and excellence in various fields.

Electronic measuring equipment plays a pivotal role in modern industries, offering precise and efficient data collection. By understanding the diverse types, their functions, and essential calibration practices, users can maximize these tools’ potential across various sectors. Regular maintenance ensures accuracy, making it crucial for professionals to stay informed about these basics to leverage electronic measuring equipment effectively.