The ultrasonic thickness gauge is a crucial tool for automotive repair and restoration, providing precise data on metal and composite materials' thickness, aiding in structural integrity checks and aesthetic assessments. Shops use this non-destructive testing method to record digital data, facilitate remote consultations, and track material changes over time. Cloud storage platforms further enhance efficiency and data integrity, ensuring superior repair quality and customer satisfaction through effective ultrasonic thickness gauge data sharing and analysis.

In today’s precision-driven manufacturing landscape, accurate material measurement is paramount. One indispensable tool for achieving this is the ultrasonic thickness gauge, a non-destructive testing device that provides critical data on material depth. This article explores how body shops—a key sector relying on precise measurements—record and securely share ultrasonic thickness gauge data, delving into the functionality of these gauges, data recording processes, and best practices for safe measurement sharing.

- Understanding Ultrasonic Thickness Gauge Functionality

- Body Shops' Data Recording Processes

- Secure Sharing of Thickness Gauge Measurements

Understanding Ultrasonic Thickness Gauge Functionality

An ultrasonic thickness gauge is a specialized tool used to measure the thickness of materials, particularly in industries like automotive repair and restoration. This non-destructive testing method sends high-frequency sound waves through a material and calculates its thickness based on the time it takes for the waves to return. In Mercedes Benz repair or any car restoration process, precision in measuring metal panels, body parts, or composite materials is crucial. The ultrasonic thickness gauge provides accurate data, ensuring that each component is replaced or repaired to exact specifications, maintaining the vehicle’s structural integrity and aesthetic appeal.

For effective record-keeping and communication among team members, body shops integrate this gauge’s data into their systems. By digitally capturing measurements, shops can easily share information, facilitate remote consultations, and compare results over time. This data sharing is particularly beneficial in complex vehicle collision repair scenarios, enabling experts to remotely assess damage and provide expert opinions without physically present at the workshop.

Body Shops' Data Recording Processes

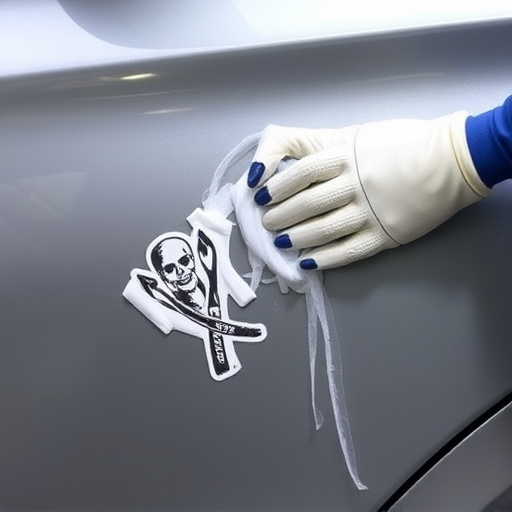

Body shops use ultrasonic thickness gauges to measure the integrity and quality of materials used in auto body repair, car paint repair, and bumper repair processes. The data recording process typically involves capturing precise measurements at various points across the surface being evaluated. This data is then meticulously logged, often in digital format for easy retrieval and analysis.

Advanced systems enable shops to store historical records, comparing current readings with previous measurements to track changes over time. This not only aids in identifying potential issues but also ensures that repairs are consistent and meet high standards. By systematically recording and sharing ultrasonic thickness gauge data, body shops can maintain accurate records, improve communication among team members, and ultimately deliver superior results for their clients.

Secure Sharing of Thickness Gauge Measurements

In today’s digital age, car body shops must ensure secure sharing of ultrasonic thickness gauge measurements to maintain data integrity and compliance. With precision instruments like ultrasonic thickness gauges, accurate record-keeping is paramount. The data collected from these devices play a crucial role in quality control processes at auto collision centers and body shops.

Secure cloud storage platforms offer a reliable solution for storing and sharing ultrasonic thickness gauge data. This ensures that measurements are easily accessible to authorized personnel across different departments or even locations, promoting seamless collaboration. For automotive repair facilities, secure data-sharing practices not only facilitate efficient workflow but also contribute to the overall quality of repairs, enhancing customer satisfaction in the process.

The efficient recording and secure sharing of ultrasonic thickness gauge data by body shops are essential practices for maintaining high standards in material inspection. By understanding the functionality of these gauges, adopting standardized data recording processes, and implementing robust security measures for measurement sharing, body shops can ensure the integrity and reliability of their work. This, in turn, promotes quality control and fosters trust among clients who rely on accurate thickness gauge measurements for their manufacturing and construction needs.