Plasma cutting collision repair revolutionizes auto industry processes by offering unprecedented precision, efficiency, and speed. This advanced technology swiftly cuts through steel, aluminum, and plastics, reducing repair times, labor costs, and vehicle downtime. By minimizing material waste and streamlining replacement processes, plasma cutting benefits customers with faster turnarounds and more affordable pricing in collision repair shops.

In the realm of automotive collision repair, plasma cutting technology emerges as a game-changer. This innovative process offers a myriad of benefits over traditional methods, ensuring efficient and precise repairs. By employing plasma cutting collision repair, technicians can achieve unparalleled accuracy, reducing waste and time. Not only does this advanced technique enhance productivity, but it also delivers cost-effective solutions without compromising quality. Embrace the future of collision repair with plasma cutting for faster, more accurate, and economical results.

- The Advantages of Plasma Cutting Technology for Collision Repair

- Efficient and Precise: How Plasma Cutting Enhances Repair Accuracy

- Cost-Effectiveness and Time-Saving Benefits of Plasma Cutting Collision Repair

The Advantages of Plasma Cutting Technology for Collision Repair

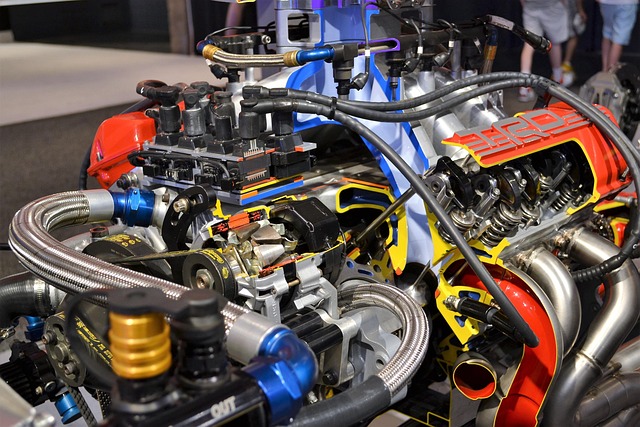

Plasma cutting technology has revolutionized the landscape of collision repair, offering numerous advantages over traditional methods. One of its key benefits is precision; this advanced technique allows for intricate and detailed cuts, ensuring that auto body restoration can be performed with exacting accuracy. This precision is particularly valuable when dealing with complex vehicle designs and hard-to-reach areas, which are common in modern automotive engineering.

Moreover, plasma cutting provides faster repair times, making it an efficient solution for busy auto repair shops and collision centers. By delivering a concentrated heat source, the technology swiftly cuts through various materials, including steel, aluminum, and even certain types of plastic. This efficiency not only reduces labor costs but also minimizes downtime for vehicles, ensuring faster turnaround times without compromising on quality or safety standards in auto collision repair processes.

Efficient and Precise: How Plasma Cutting Enhances Repair Accuracy

Plasma cutting collision repair stands out as a game-changer in the automotive restoration realm. Unlike traditional cutting methods, plasma cutting offers unprecedented efficiency and precision. This advanced technique utilizes a high-velocity stream of ionized gas to cut through materials with remarkable accuracy, minimizing heat impact and distortion.

In the context of vehicle dent repair and car paint repair, plasma cutting is particularly beneficial for its ability to navigate intricate shapes and contours without compromising the surrounding bodywork. By delivering clean, crisp cuts, it enhances the overall precision and quality of car bodywork repairs, ensuring that each component aligns perfectly with the original factory specifications.

Cost-Effectiveness and Time-Saving Benefits of Plasma Cutting Collision Repair

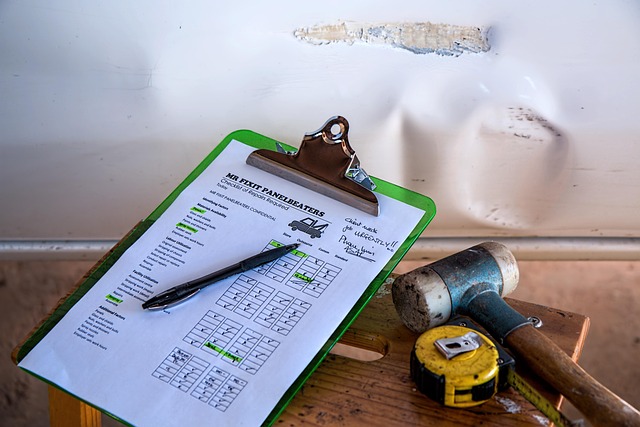

Plasma cutting collision repair offers significant cost-effectiveness and time-saving benefits for both businesses and individuals in need of auto body work or auto dent repair. Traditional methods, such as torching, often require more labor-intensive processes that can lead to higher costs and longer turnaround times. In contrast, plasma cutting streamlines the collision repair process by providing precise, efficient cuts, reducing the amount of material waste, and minimizing the overall time required for repairs.

This advanced technique is particularly advantageous in a collision repair shop setting. By employing plasma cutting technology, technicians can quickly and accurately remove damaged or affected panels, facilitating faster replacement and repainting processes. As a result, customers benefit from reduced wait times and more affordable pricing, making plasma cutting collision repair an attractive option for anyone seeking top-quality auto body work without the usual costs and delays associated with conventional methods.

Plasma cutting collision repair offers a multitude of benefits that traditional methods simply cannot match. Its efficient and precise nature streamlines the repair process, reducing both costs and time without compromising accuracy. By embracing this innovative technology, collision repair facilities can enhance their operational efficiency, deliver superior results, and stay ahead in an increasingly competitive market.