The evolution of auto glass safety standards, driven by technological advancements and passenger protection concerns, has transformed the industry. Stricter requirements include rigorous impact and penetration testing, noise reduction, and materials science innovations like laminate glass. Advanced driver-assistance systems (ADAS) emphasize the importance of high-quality auto glass in modern luxury vehicles. Modern manufacturing processes, guided by standards from AGSS and ANSI Z202, ensure precise cutting and tempering for enhanced structural integrity. The automotive industry's focus on auto glass safety includes impact resistance, crack prevention, and proper installation techniques, reducing injury risks during accidents. Specialized technicians ensure secure repairs and replacements, contributing to safer vehicles for all road users.

Is auto glass safety still a priority in today’s advanced automotive landscape? This question prompts an in-depth look at the evolution of auto glass manufacturing and its adherence to stringent safety standards. Over time, these standards have revolutionized the industry, ensuring stronger, more impact-resistant glass. Understanding the modern production processes and their compliance with safety regulations is key. By examining these factors, we can assess whether contemporary auto glass lives up to its safety reputation.

- Auto Glass Safety Standards: Evolution Over Time

- Understanding Modern Auto Glass Manufacturing

- The Impact of Improved Safety Regulations

Auto Glass Safety Standards: Evolution Over Time

The auto glass safety standards have undergone a significant evolution over time, driven by advancements in technology and an increasing focus on passenger protection. Initially, auto glass was primarily designed to prevent shattering, but modern standards go far beyond basic durability. Today, regulations mandate rigorous testing for impact resistance, penetration resistance against debris, and even noise reduction capabilities. These standards are continually updated to reflect the evolving landscape of vehicle design and safety technology.

For instance, advancements in materials science have led to the development of laminate auto glass, which is designed to crumple and absorb energy during a collision, enhancing overall vehicle safety. Moreover, the integration of advanced driver-assistance systems (ADAS) has further emphasized the need for superior auto glass safety. Features like lane departure warning and adaptive cruise control rely on clear, unobstructed visibility provided by high-quality auto glass, making it an integral component in modern vehicles, including luxury brands like Mercedes Benz collision repair services, which prioritize both aesthetics and safety in their repairs.

Understanding Modern Auto Glass Manufacturing

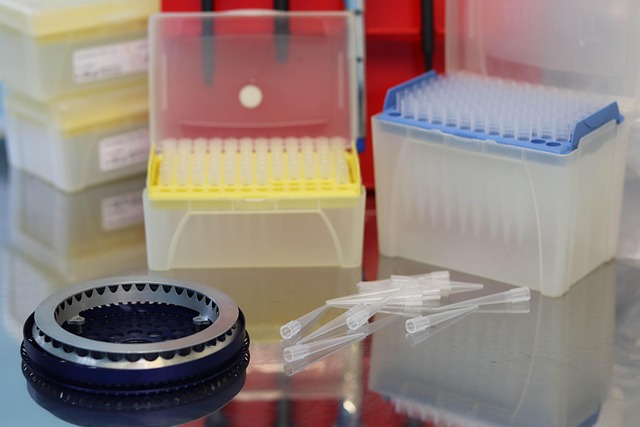

Modern auto glass manufacturing has evolved significantly, driven by stringent safety standards and advancements in technology. Today, auto glass is produced using state-of-the-art machinery that ensures precise cutting, shaping, and tempering processes. These techniques not only enhance the structural integrity of the glass but also improve its impact resistance, a crucial aspect of auto glass safety.

The industry adheres to rigorous safety protocols, including adherence to standards set by organizations like the Auto Glass Safety Standard (AGSS) and ANSI Z202. These standards dictate the quality and performance requirements for all auto glass products, ensuring that each pane is designed to withstand severe impacts without shattering into sharp fragments. Additionally, modern cars incorporate advanced safety features such as laminated glass, which further bolsters the protection offered by vehicle repair shops, especially during frame straightening processes.

The Impact of Improved Safety Regulations

The automotive industry has witnessed significant advancements in safety standards over the years, and auto glass safety is no exception. Stricter regulations have been implemented to ensure that vehicle windows and windshields meet robust safety criteria, thereby enhancing driver and passenger protection. These improvements are a direct response to the critical role auto glass plays in structural integrity during accidents. Modern safety standards focus on impact resistance, crack prevention, and proper installation techniques.

With enhanced safety regulations, drivers can rest assured that their vehicles’ auto glass is more durable and reliable. This advancement not only reduces the risk of injuries but also provides peace of mind while on the road. Moreover, many collision centers now employ specialized technicians who are trained to handle auto glass repairs and replacements, ensuring a secure fit and adhering to the latest safety guidelines. This focus on auto glass safety standards is a significant step towards making vehicles safer for everyone on the roads, including those seeking car dent repair services near them.

In light of the above discussions on auto glass safety standards, evolution in manufacturing processes, and the impact of improved regulations, it’s clear that auto glass safety remains a paramount concern. Continuous advancements in materials science and stringent international standards ensure that today’s auto glass is stronger, more impact-resistant, and safer than ever before. As technology continues to evolve, so too will auto glass safety, further enhancing passenger protection on the road.