3D vehicle scanning technology is revolutionizing the automotive industry by providing a comprehensive, non-invasive solution for structural damage assessment. This advanced method offers precise measurements and high-resolution models of both interior and exterior vehicles, enabling technicians to identify even subtle damage. It's particularly valuable for car body shops and collision repair centers, leading to improved quality outcomes for customers through thorough inspections and accurate repairs.

“Unveiling the power of technology, 3D vehicle scanning is revolutionizing automotive maintenance. This advanced process captures intricate vehicle structures in digital depth, offering a comprehensive view unseen by traditional methods. By understanding 3D scanning technology and its role in detecting structural defects, we unlock a new era of precision inspection.

This article explores how 3D scanning benefits the automotive industry, ensuring safer vehicles and efficient troubleshooting.”

- Understanding 3D Vehicle Scanning Technology

- The Role of 3D Scanning in Detecting Structural Defects

- Benefits and Applications in the Automotive Industry

Understanding 3D Vehicle Scanning Technology

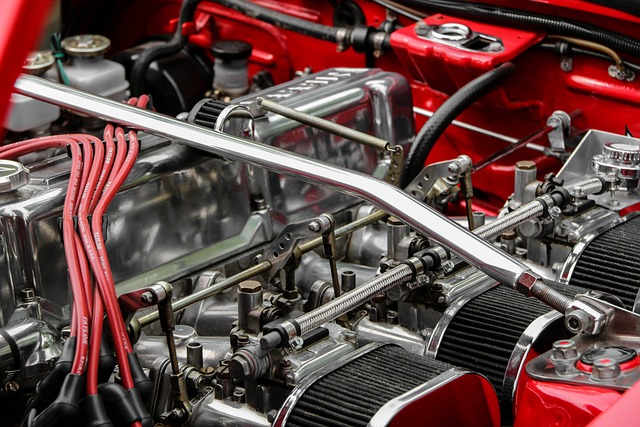

3D vehicle scanning technology is revolutionizing the way automotive professionals assess and address structural damage. Unlike traditional methods relying on manual inspection and 2D imaging, this advanced technology offers a comprehensive digital solution. By capturing intricate details of a vehicle’s exterior and interior, 3D scanners create accurate, high-resolution models that provide a clear picture of any damage or discrepancies.

This innovative approach is particularly beneficial for car body shops and those involved in vehicle collision repair and auto body restoration. It enables precise measurements, allowing technicians to identify even the subtlest deformities, cracks, or misalignments. With 3D scanning, the process becomes more efficient, ensuring that every angle is examined thoroughly before proceeding with any repairs, ultimately leading to higher-quality outcomes for customers across the board.

The Role of 3D Scanning in Detecting Structural Defects

3D scanning technology has revolutionized the way structural defects in vehicles are detected and diagnosed. Unlike traditional methods that rely heavily on visual inspection and manual measurements, 3D vehicle scanning provides a non-invasive, accurate, and detailed digital representation of a car’s exterior and interior. This advanced technique captures every curve, contour, and crevice, enabling auto collision centers to uncover even the most subtle structural issues that might be missed during manual assessments.

By generating highly precise 3D models, scanning technology facilitates comprehensive comparisons between original vehicle specifications and any existing damage or wear. This capability is invaluable in various scenarios, including vehicle restoration projects and assessing damages following car paint services. With 3D scanning, restorers can accurately pinpoint areas of concern, plan repair strategies, and ensure that every part of the vehicle is restored to its original state with meticulous precision, resulting in superior quality work.

Benefits and Applications in the Automotive Industry

The automotive industry has witnessed a significant transformation with the advent of 3D vehicle scanning technology. This advanced process offers numerous benefits in detecting and addressing structural issues within vehicles, which is a critical aspect of safety and performance. By creating precise digital representations of vehicles, 3D scanning enables thorough inspections that can uncover hidden damage or deformities often missed by traditional methods. It plays a pivotal role in collision repair shops and auto body restoration facilities, ensuring that every vehicle undergoes comprehensive evaluation before and after repairs.

One of the key applications is in car paint repair processes. 3D scanning technology allows for exact measurements and analysis of the vehicle’s exterior, helping to determine the extent of paint damage. This precision leads to more effective and efficient repainting, resulting in a superior finish. Moreover, it aids in quality control by comparing post-repair scans with original data, guaranteeing that structural integrity is restored seamlessly, ensuring customer satisfaction and safety on the road for all vehicle types.

3D vehicle scanning technology is transforming how structural issues are identified and addressed in the automotive industry. By creating detailed digital models of vehicles, this innovative process allows for meticulous inspection, enabling professionals to detect even the most subtle defects. With its precision and efficiency, 3D scanning offers a game-changing approach to quality control, ensuring safer and more reliable vehicles on the road.