Aluminum panel dent repair is a specialized auto maintenance service using various tools and technologies to minimize scarring and preserve structural integrity. Aluminum's lightweight, corrosion-resistant properties make it a preferred material for modern vehicles, simplifying repairs and enhancing fuel efficiency. This guide offers a step-by-step process for effective aluminum panel dent removal, ensuring high-quality autobody repairs.

Aluminum panel dent repair is a game-changer in auto maintenance, offering efficient and cost-effective solutions for car owners. As vehicles increasingly embrace lightweight aluminum bodies, understanding how to effectively fix dents becomes essential. This article delves into the art of aluminum panel dent repair, exploring techniques, benefits, and providing a comprehensive step-by-step guide to ensure optimal results. Discover how this skill can preserve your vehicle’s aesthetics and value.

- Understanding Aluminum Panel Dent Repair Techniques

- Benefits of Using Aluminum for Auto Body Repairs

- Step-by-Step Guide to Effective Aluminum Panel Dent Removal

Understanding Aluminum Panel Dent Repair Techniques

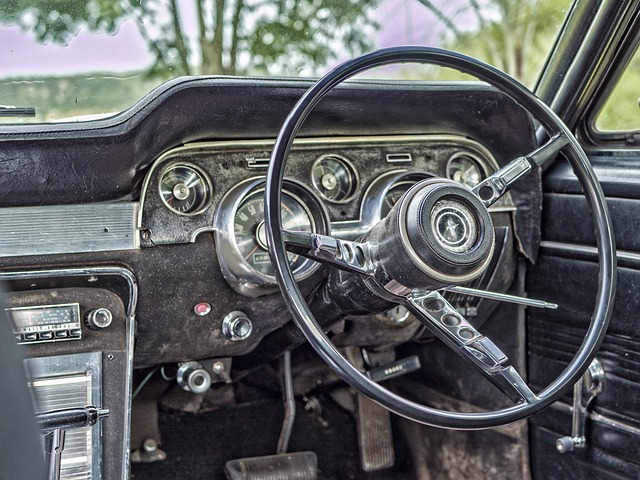

Aluminum panel dent repair is a specialized technique within the broader field of auto maintenance. It involves restoring damaged or dented aluminum car panels to their original condition, often after incidents like hail damage or minor accidents. This process requires a deep understanding of the material’s properties and unique repair methods.

Professionals in this domain employ various techniques, from manual straightening and shaping using specialized tools to more advanced technologies like laser-based repairs and automated dent removal machines. The goal is to minimize scarring and ensure the car body’s structural integrity remains intact. This meticulous process not only enhances the aesthetics of the vehicle but also plays a significant role in preserving its overall value, especially for those looking to keep their cars in top condition through regular auto maintenance routines.

Benefits of Using Aluminum for Auto Body Repairs

Aluminum has become a popular choice for auto body repairs, particularly in aluminum panel dent repair. One of its key benefits is its exceptional lightweights compared to traditional materials like steel. This makes it ideal for modern vehicles that prioritize fuel efficiency and improved performance. Aluminum’s lightweight nature also translates into easier handling during the repair process, reducing labor costs and potential damage.

Furthermore, aluminum offers superior corrosion resistance, making it a durable choice for vehicle restoration. Its smooth surface is more susceptible to a pristine finish, ensuring vehicles maintain their aesthetic appeal even after repairs. The material’s versatility allows for complex shaping, enabling precise dent repair and meticulous bodywork, ultimately contributing to the overall quality of autobody repairs.

Step-by-Step Guide to Effective Aluminum Panel Dent Removal

Aluminum panel dent removal is a specialized skill crucial for efficient auto maintenance, especially post-collisions. Here’s a step-by-step guide to ensure successful aluminum panel dent repair:

1. Inspection: Begin by meticulously inspecting the dented area. Identify its size, depth, and location on the vehicle. Different parts of a car have varying levels of complexity in their structure, so understanding these nuances is essential for effective repair.

2. Preparation: Gather all necessary tools and materials such as a dent puller, mallet, and a heat gun (optional). Clean the panel to ensure no debris or contaminants are present. This step is vital as it guarantees that the repair job will be of the highest quality. In a collision repair center, this preparation phase also includes careful assessment by skilled technicians who employ advanced tools for accurate measurements and planning.

3. Heat Application (if applicable): Use a heat gun to warm up the dented area gently. Heat softens the aluminum, making it easier to manipulate without causing further damage. This step is particularly useful for larger or deeper dents.

4. Dent Removal: Using the dent puller and mallet, carefully apply force in specific areas around the dent to start pulling it out. Work methodically, applying pressure at different angles to avoid damaging nearby panels or components. The goal is to remove the dent while ensuring minimal deformation to the surrounding area.

5. Finishing Touches: Once the dent is removed, smoothen any remaining ridges with a putty knife or similar tool. Clean and dry the panel thoroughly before applying any primers or paints for a seamless finish, matching the vehicle’s original color. This meticulous finishing process ensures that the repaired area looks uniform with the rest of the vehicle, especially in high-quality auto repair services.

Aluminum panel dent repair has emerged as a game-changer in auto maintenance, offering efficient and durable solutions for car body repairs. By understanding the unique techniques and benefits of this method, drivers can ensure their vehicles’ aesthetics and structural integrity are maintained. With its versatility and light weight, aluminum proves to be an ideal choice for modern cars, enabling faster repairs and long-lasting results. This step-by-step guide highlights the key processes involved, empowering car owners to take control of their vehicle’s upkeep and experience the advantages of aluminum panel dent repair.