PDR for steel panels is a modern auto repair technique that avoids sanding and repainting, preserving original factory finishes. It's efficient, cost-effective, and popular for swift repairs, especially when considering nearby services like "auto body work near me". However, it requires specialized skills and equipment to handle unique challenges like dent depth, structural integrity concerns, and weather conditions.

Is PDR (Panel Damage Repair) still a valuable investment for steel panel repairs? In today’s competitive market, this modern approach deserves our attention. This article explores the benefits of PDR for steel panels, focusing on its time and cost efficiency. We’ll also delve into potential challenges and considerations, providing insights to help you decide if PDR is the right choice for your needs. By understanding PDR’s impact, you can make an informed decision.

- Understanding PDR: A Modern Approach for Steel Panels

- Benefits of PDR: Time and Cost Efficiency

- Challenges and Considerations in Implementing PDR Techniques

Understanding PDR: A Modern Approach for Steel Panels

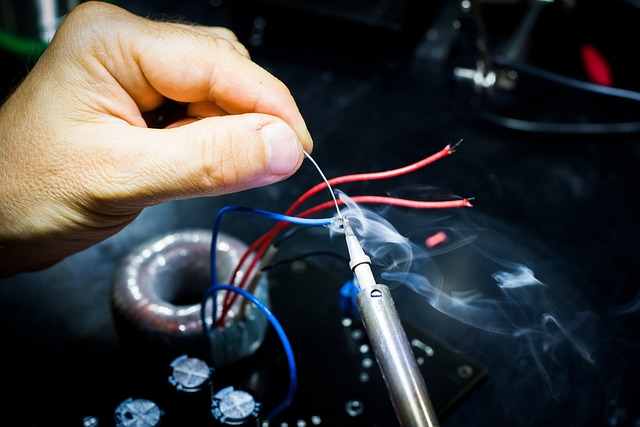

PDR, or Paintless Dent Repair, is a modern technique that has revolutionized auto repair services, especially for steel panels. It’s an innovative approach to automotive restoration that avoids the traditional time-consuming and often costly methods of auto body repair. By using specialized tools and techniques, PDR allows technicians to remove dents and dings from vehicle surfaces without sanding or repainting. This not only saves on materials but also reduces the time required for repairs, making it a more efficient process.

The benefits of PDR for steel panels are significant. It preserves the original factory finish, ensuring that vehicles maintain their aesthetic appeal. Moreover, since no painting is involved, there’s less risk of color mismatch or imperfections often seen in conventional auto body repair. This makes PDR particularly appealing to car owners who value both the look and integrity of their vehicle’s exterior. As a result, many automotive restoration specialists are adopting this technique as a primary service offering, catering to customers seeking high-quality, swift, and cost-effective solutions for their steel panel repairs.

Benefits of PDR: Time and Cost Efficiency

PDR for steel panels offers a unique advantage in terms of time and cost efficiency when compared to traditional auto body work methods. This non-invasive technique has revolutionized the way we repair minor dents and scratches on metal surfaces, particularly in the automotive industry. By utilizing specialized tools and trained technicians, PDR (Paintless Dent Repair) can restore damaged steel panels back to their original condition without the need for extensive sanding, painting, or body panel replacement.

This efficiency translates into significant savings for both repair shops and vehicle owners. With PDR, there’s no need to spend time on intricate paint matching or complex primer application, which are often required in collision damage repair processes. This streamlined approach not only reduces labor costs but also cuts down on the overall duration of the repair process, making it a more attractive option for those seeking swift and economical solutions for their auto repairs, especially when considering nearby auto repair services (auto body work near me).

Challenges and Considerations in Implementing PDR Techniques

Implementing PDR (Paintless Dent Repair) techniques for steel panels presents a unique set of challenges and considerations. While PDR has revolutionized car bodywork services by offering an efficient, cost-effective alternative to traditional paint jobs, its application on steel requires specialized skills and equipment. Unlike vehicle paint repair methods that focus primarily on aesthetics, PDR for steel panels must also account for structural integrity, as dents in steel can compromise the panel’s strength over time if not addressed properly.

The process involves careful assessment of the damage, including identifying the depth and location of the dent, which determines the feasibility of PDR. Unlike car scratch repair, where minor imperfections can often be removed with relative ease, significant dents in steel panels may require more aggressive techniques or even replacement parts. Moreover, weather conditions play a crucial role, as temperature and humidity levels can impact the effectiveness of PDR and the final finish quality. Thus, technicians must adapt their methods based on these factors to ensure the best possible outcomes for steel panel repairs.

PDR for steel panels continues to prove its worth as a modern, efficient solution for repairing minor damage. While challenges exist, the benefits of time and cost savings make it a compelling choice for many. By understanding the process and addressing potential hurdles, professionals can leverage PDR techniques to provide high-quality repairs that preserve the appearance and longevity of steel panels, ensuring a smart investment for years to come.