PDR for aluminum panels specializes in fixing dents and scratches on automotive aluminum without repainting. Skilled technicians use precise tools to manipulate dented areas, restoring panels to original shape and integrity. Modern advanced tools transform PDR, addressing material's delicate nature while streamlining car collision repair processes, achieving high-quality, precise restorations.

In the realm of panel restoration, Professional Detailing Repair (PDR) has emerged as a game-changer, particularly for aluminum panels. This non-invasive technique promises meticulous results and efficient repairs. This article delves into the intricate world of PDR for aluminum, exploring effective techniques and highlighting essential tools that contribute to precise and swift panel restoration. Unlocking the potential of advanced tools, we examine how they maximize restoration outcomes, ensuring a vibrant and like-new finish.

- Understanding PDR Techniques for Aluminum Panels

- Essential Tools for Efficient PDR on Aluminum

- Maximizing Panel Restoration with Advanced Tools

Understanding PDR Techniques for Aluminum Panels

PDR, or Paintless Dent Repair, is a specialized technique designed for repairing dents and dings on automotive panels, particularly aluminum ones. When it comes to PDR for aluminum panels, understanding the unique characteristics of this metal is crucial. Aluminum is lightweight, durable, and highly resistant to corrosion, making it a popular choice in modern vehicle manufacturing. However, its soft nature makes it susceptible to dents, especially during fender benders or tire services.

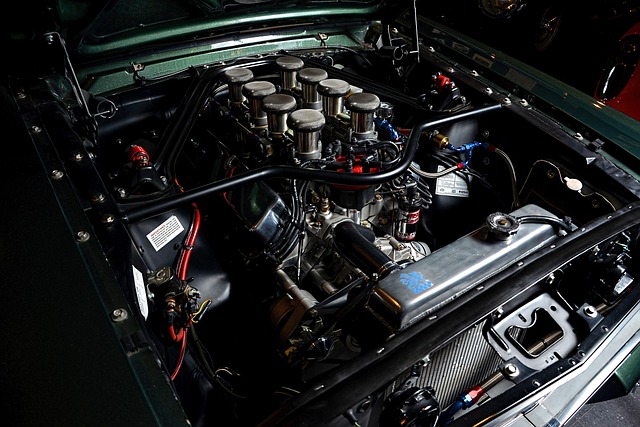

The techniques employed in PDR for aluminum panels involve careful manipulation of specialized tools to remove the dent without damaging the paint or surface. This process requires skilled technicians who can assess the damage and select the appropriate tools. By using the right equipment, such as rubber mallets, slide hammers, and plastic tools, professionals can gently work around the dented area, returning the panel to its original shape while maintaining the integrity of the aluminum. This method is particularly advantageous for minor dents and scratches, offering an efficient and cost-effective alternative to traditional paint repair in vehicle collision repair scenarios.

Essential Tools for Efficient PDR on Aluminum

In the realm of automotive restoration, particularly for PDR (Paintless Dent Repair) on aluminum panels, the right tools are indispensable. For efficient and effective PDR for aluminum panels, professionals rely on a set of specialized equipment tailored to handle the unique properties of aluminum. These include precision dent pullers, which use controlled force to remove dents without damaging the paint or surface, and various types of tampers for even and precise pressure application.

Additionally, microfiber cloths and polishers are essential for achieving a flawless finish after removing the dent. They ensure that no scratch repair is left behind and the car dent repair process results in a virtually invisible fix. This level of detail is crucial when it comes to auto repair services, especially for clients seeking top-notch aesthetics without the need for repainting.

Maximizing Panel Restoration with Advanced Tools

In the realm of PDR for aluminum panels, advanced tools play a pivotal role in maximizing restoration quality and efficiency. These innovative solutions are designed to cater to the unique challenges posed by aluminum’s inherent properties, such as its lightweight yet delicate nature. By employing modern technology, automotive body work specialists can achieve precise, seamless results that restore panels to their original condition, almost like new.

The integration of these advanced tools offers a significant edge in car collision repair processes. From specialized dent removal equipment to sophisticated measurement devices, each tool contributes to an enhanced workflow. This not only expedites tire services but also ensures accuracy, minimizing the risk of damage or imperfections. As a result, the final restoration meets the highest standards, providing customers with exceptional value and peace of mind.

In conclusion, understanding and mastering PDR for aluminum panels requires a blend of technical knowledge and the right tools. By familiarizing ourselves with various PDR techniques tailored for aluminum, we can efficiently restore damaged panels. The essential tools discussed in this article play a pivotal role in streamlining the process, ensuring precise and effective results. Furthermore, exploring advanced tools offers even more opportunities to maximize panel restoration quality, making it a valuable investment for professionals in the industry.