Virtual Estimating Collision (VEC) revolutionizes automotive repair by creating digital vehicle models for precise pre-work cost and timeline estimates. This immersive 3D view enhances efficiency for collision repair centers, tire services, and dent specialists, reducing delays and streamlining initial evaluations. VEC allows technicians to virtually navigate vehicles, accurately identifying repair needs and improving workflow, ultimately providing quicker turnarounds and enhanced customer satisfaction through transparent, accurate estimates.

In today’s fast-paced project management landscape, minimizing delays is crucial. Virtual Estimating Collision (VEC) emerges as a game-changer, revolutionizing how teams schedule and execute projects. This article delves into the world of VEC, exploring its benefits over traditional methods and providing insights on seamless implementation. By understanding collision estimates and leveraging technology, teams can navigate complex tasks more effectively, ensuring projects stay on track without unwanted delays.

- Understanding Virtual Estimating Collision

- Advantages Over Traditional Methods

- Implementing for Seamless Project Management

Understanding Virtual Estimating Collision

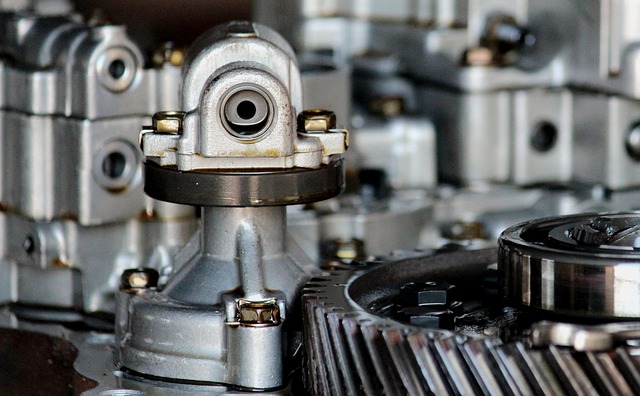

Virtual Estimating Collision (VEC) is a groundbreaking technology that allows professionals in the automotive industry to assess and plan repairs virtually, before any physical work begins. By creating a digital model of a vehicle, including its intricate details and potential damage, VEC offers a precise method for estimating collision repair costs and timelines. This innovative approach streamlines the initial evaluation process, enabling quick decision-making and efficient scheduling.

Unlike traditional methods relying on manual inspections, VEC provides an immersive, 3D view of the vehicle’s inner workings, revealing hidden components and potential issues. This technology is particularly beneficial for collision repair centers, tire services, and car dent repair specialists, as it helps avoid delays caused by unexpected damage or complexity in repairs. With VEC, technicians can virtually navigate around the vehicle, identifying the extent of the work required, ensuring a smoother workflow, and ultimately, delivering faster turnarounds to customers.

Advantages Over Traditional Methods

In the realm of vehicle repair services, adopting virtual estimating collision techniques offers a myriad of advantages over traditional, manual approaches. One of the key benefits is the ability to streamline the entire process, from initial assessment to final billing. With virtual tools, technicians can meticulously inspect and document collision damage with enhanced accuracy, ensuring every detail is captured for precise repairs. This digital method not only saves time but also minimizes errors that often arise from hand-drawn estimates.

Furthermore, virtual estimating collision provides a comprehensive view of the vehicle’s structure and components. This allows for more effective frame straightening and collision damage repair procedures, as technicians can virtually simulate the restoration process before executing it physically. Such technological advancement promotes efficiency, reduces waste, and ultimately leads to faster turnaround times, benefiting both repair shops and customers alike.

Implementing for Seamless Project Management

Implementing virtual estimating collision technologies is a game-changer for project management in auto repair shops, specifically those offering vehicle dent repair services. This innovative approach streamlines the process of assessing damage and creating accurate repair estimates, eliminating many delays caused by manual methods. By using advanced digital tools, auto repair professionals can swiftly capture and analyze collision-related data, ensuring every detail is considered before a quote is provided.

This seamless integration benefits both repair shop owners and customers. For auto repair near me services, virtual estimating allows for faster turnaround times as estimators can work remotely and make real-time decisions. It also reduces human error, improves communication, and enhances customer satisfaction by providing transparent and precise cost estimates for vehicle dent repair.

Virtual estimating collision is a game-changer in project management, offering seamless scheduling and reduced delays. By leveraging this technology, teams can efficiently manage resources, predict potential conflicts, and optimize timelines. In contrast to traditional methods, it provides an accurate, real-time view of project progress, ensuring every task is accounted for. Implementing virtual estimating collision is a strategic move towards successful project delivery, allowing for better control and enhanced collaboration among stakeholders.