Corrosion protection costs vary based on materials, environment, and treatment methods. High-quality coatings, vehicle size, complex conditions, and labor intensity impact pricing. Effective corrosion protection requires strategic budgeting, risk assessment, and resource allocation for maintenance, coatings, and repairs. Proactive measures like regular inspections and preventive treatments significantly reduce expenses and prolong asset lifespans.

Corrosion protection is a critical aspect of any asset management strategy, yet budgeting for it can be complex. This article guides you through the key cost factors influencing corrosion protection, empowering you to make informed decisions. We’ll explore how to budget effectively for corrosion prevention and provide valuable tips to optimize spending. By understanding these elements, you’ll be better equipped to minimize corrosion-related expenses and prolong the lifespan of your assets.

- Understanding Corrosion Protection Costs: Factors at Play

- Budgeting Strategies for Effective Corrosion Prevention

- Optimizing Spending: Tips to Minimize Corrosion-Related Expenses

Understanding Corrosion Protection Costs: Factors at Play

Understanding Corrosion Protection Costs: Factors at Play

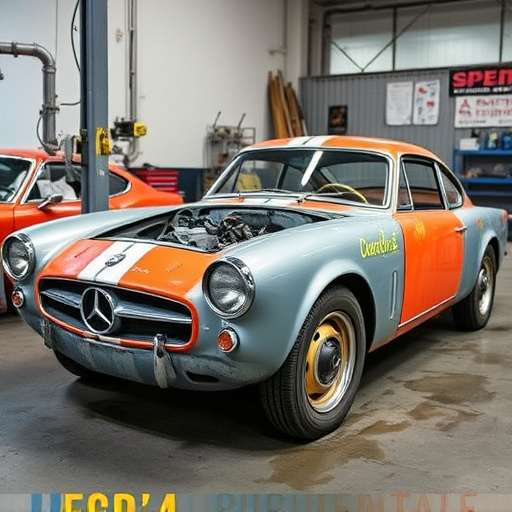

Corrosion protection goes beyond merely preventing rust; it involves a complex interplay of materials, environment, and treatment methods. The cost of corrosion protection in automotive repair, car body restoration, and auto body repairs varies widely due to these factors. For instance, protective coatings like paint or specialized sealing agents carry different price tags based on their quality, durability, and the complexity of application. Additionally, the size and condition of the vehicle play significant roles; a larger vehicle with extensive corrosion damage will require more intensive treatments, thereby increasing costs.

Environmental conditions are another critical component. Regions with high humidity, extreme temperatures, or salty air demand more robust corrosion protection measures, such as specialized undercoatings or additional sealing layers. Moreover, labor costs vary based on the skill and time required for application—a meticulous, multi-step process can significantly impact the overall price of corrosion protection services in automotive repair, car body restoration, and auto body repairs.

Budgeting Strategies for Effective Corrosion Prevention

Effective corrosion protection requires a strategic approach to budgeting, especially for businesses operating in industries where metal structures and vehicles are exposed to harsh environments. The first step is to conduct a thorough assessment of all assets prone to corrosion, such as industrial machinery, infrastructure, and vehicle fleets. This involves identifying high-risk areas and considering the extent of necessary treatments, ranging from simple coatings to complex surface treatments for severe cases.

Once risks are assessed, create a detailed budget that allocates resources accordingly. Prioritize essential measures like regular maintenance, which can prevent corrosion in the first place, cost-effective coatings, and timely replacement of damaged components. For instance, investing in professional vehicle restoration services or body shop repairs to fix rusted areas before they spread can save significant costs compared to the price of a complete overhaul later.

Optimizing Spending: Tips to Minimize Corrosion-Related Expenses

Optimizing spending on corrosion protection is a strategic move to minimize expenses over time. Regular maintenance and early intervention can significantly reduce costs associated with extensive repairs later. Implement preventive measures such as applying protective coatings, sealing vulnerable areas, and conducting routine inspections to identify potential issues before they become major problems. This proactive approach not only saves money but also prolongs the lifespan of assets, be it a vehicle body, building structures, or industrial equipment.

When budgeting for corrosion protection, consider cost-effective solutions that offer long-lasting protection without breaking the bank. For instance, opting for specialized paints and coatings designed to resist corrosion can be more affordable than frequent repainting or repairs. Additionally, exploring eco-friendly alternatives or recycled materials for auto painting or vehicle body repair might reduce expenses while promoting sustainability. Remember, a well-planned strategy tailored to your specific needs will ensure efficient spending on corrosion protection measures.

Corrosion protection is an essential investment for any asset owner, but understanding and budgeting for these costs can be challenging. By recognizing the key cost factors discussed in this article—from material types to environmental conditions—and implementing strategic budgeting tips, businesses can effectively manage and minimize their corrosion-related expenses. Staying proactive through regular maintenance and leveraging modern corrosion protection technologies will help extend the lifespan of critical infrastructure, ensuring long-term savings and operational efficiency.