Before plastic welding collision repairs, assess damage, consider material compatibility, and choose appropriate techniques (hot gas, ultrasonic, robotic) for seamless blending, maintaining structural integrity and aesthetic appeal with meticulous cleaning, priming, sanding, and buffing.

“After a plastic welding collision, seamless repairs are crucial for maintaining integrity and aesthetics. This guide delves into the art of blending plastic welds, offering a step-by-step approach to achieving flawless results. Before repairing, carefully evaluate damage to ensure accurate assessment and select suitable welding techniques tailored to your plastic material. Our comprehensive tutorial ensures you master the process, resulting in seamless blends that conceal repair marks.”

- Evaluating Damage: Assess Before Repairing

- Selecting Suitable Plastic Welding Techniques

- Achieving Seamless Blending: Step-by-Step Guide

Evaluating Damage: Assess Before Repairing

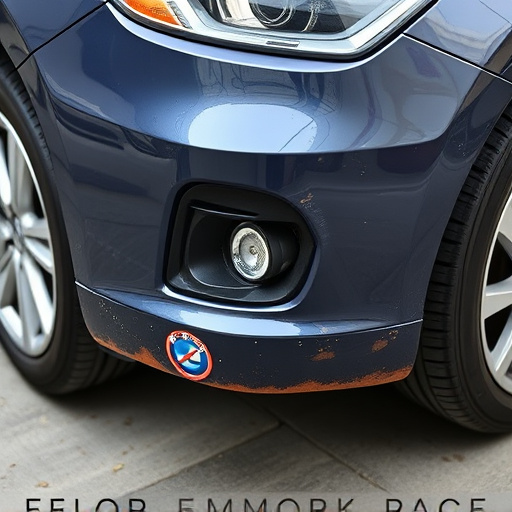

Before attempting any plastic welding repairs, it’s crucial to thoroughly evaluate the damage caused by a collision or fender bender. This initial assessment will determine the extent of the work required and help ensure seamless results after the repair process is complete. Start by inspecting the affected area for cracks, breaks, or deformations in the plastic components, such as car bumpers or fenders. These visible signs can provide valuable insights into the severity of the damage and the type of repairs needed.

Additionally, consider factors like material compatibility, as different plastics may require specific welding techniques and materials to achieve a strong bond. Consulting with experienced auto repair services or referring to manufacturer guidelines can be beneficial in understanding these nuances. By taking the time to assess the damage carefully, you’ll be better prepared to blend plastic welds seamlessly, ensuring that any repairs are not only functional but also virtually invisible, maintaining the vehicle’s original appearance after a bumper or fender bender.

Selecting Suitable Plastic Welding Techniques

When it comes to blending plastic welds seamlessly after repairs, selecting the right welding technique is paramount. Different plastics require distinct approaches to ensure a strong and invisible bond. For instance, in the realm of vehicle repair, especially with high-end brands like Mercedes Benz, precise frame straightening often involves specialized plastic welding methods tailored for specific components.

The choice of welding technique depends on factors such as the type of plastic, the size and complexity of the repair, and the desired aesthetic outcome. In collision repair scenarios, professionals might employ hot gas welding, ultrasonic welding, or even robotic welding to create seamless joints. Each method has its advantages, ensuring either rapid bonding for larger pieces or meticulous, fine-tuned repairs for intricate parts, ultimately enhancing the overall quality of the vehicle repair.

Achieving Seamless Blending: Step-by-Step Guide

Achieving seamless blending after plastic welds is a critical step in ensuring the structural integrity and aesthetic appeal of collision-damaged vehicles, be it for auto glass repair or tire services. It requires precision, patience, and a methodical approach to match the original finish perfectly. Here’s a step-by-step guide:

1. Preparation: Begin by thoroughly cleaning the weld area using appropriate solvents to remove any grease, dust, or debris. Ensure the surface is dry before proceeding. For best results in vehicle repair services, consider using specialized primers designed for plastic welding, which can help with adhesion and blending.

2. Sand and Buff: Lightly sand the welded area using fine-grit sandpaper to smooth out any imperfections. This process helps create a slightly textured surface that allows for better paint adherence. After sanding, use a buffer to achieve a smooth finish, removing any remaining scratches or rough edges. Keep in mind, this step is crucial for seamless blending as it ensures the new plastic matches the existing surface texture.

When repairing and blending plastic welds, the key lies in meticulous evaluation, choosing the right techniques, and precise execution. By following these steps and utilizing appropriate plastic welding methods for specific materials, you can achieve seamless results that match the original integrity of the plastic surface, effectively minimizing the impact of any collision damage.