A thorough damage assessment is crucial for effective AC system collision repair after a rear-end crash. Advanced diagnostic tools and trained professionals inspect components like refrigerant lines, condensers, evaporators, and thermostats for any compromised integrity or misalignment. This meticulous process ensures targeted repairs, prevents further complications, and restores seamless AC functionality while maintaining vehicle aesthetics and structural integrity.

In the aftermath of a rear-end vehicle accident, assessing and repairing the AC system is crucial for restoring comfort. This article delves into the intricate details of AC system collision repair, specifically tailored to rear-end collisions. We explore common components affected, providing a comprehensive guide on their assessment and replacement. By understanding the process, you’ll gain insights into effective reconstruction techniques, ensuring your vehicle’s cooling efficiency is restored seamlessly.

- Assessing Damage to AC System After Rear-End Collisions

- Common Components Affected in Vehicle Accident AC Repair

- Restoring Cooling Efficiency: Step-by-Step AC System Reconstruction

Assessing Damage to AC System After Rear-End Collisions

After a rear-end collision, assessing damage to the AC system is crucial for effective AC system collision repair. While initial inspections may reveal obvious signs like dents or leaks, more subtle issues could exist. Techs at reputable collision centers employ advanced diagnostic tools to scrutinize components such as refrigerant lines, condensers, evaporators, and thermostats for any compromised integrity or misalignment. Proper evaluation ensures targeted repairs, preventing further complications.

Understanding the intricate nature of modern AC systems demands specialized knowledge and skills in vehicle body repair. Collision centers with trained professionals utilize their expertise to identify damage that may not be immediately apparent. This includes assessing corrosion, wear and tear, or disruptions in the refrigerant cycle caused by impact. Prompt and accurate diagnosis facilitates efficient repairs, restoring your vehicle’s comfort and ensuring a seamless driving experience once again.

Common Components Affected in Vehicle Accident AC Repair

In a rear-end vehicle accident, several components of the AC system can be affected. The most common issues include damage to the compressor, condenser, and evaporator coils. These parts work together to circulate and cool the refrigerant gas, which is essential for maintaining comfortable temperatures inside the vehicle. When involved in a collision, these components may sustain physical damage, leading to leaks or loss of cooling performance.

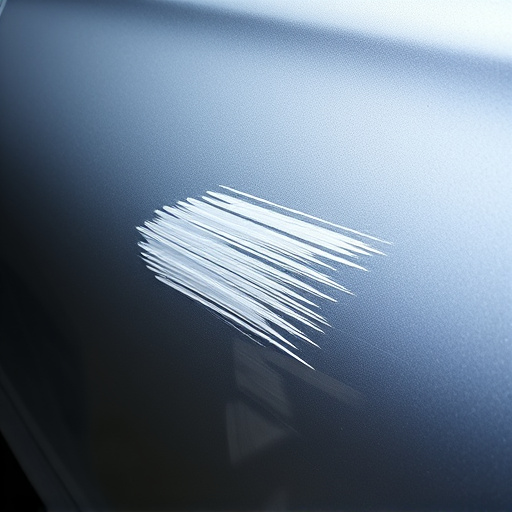

Additionally, the thermal expansion valve (TEV) and the receiver/drier can also be impacted. The TEV regulates the flow of refrigerant, while the receiver/drier absorbs moisture from the system, preventing corrosion and condensation issues. Damage to these parts can disrupt the entire AC system’s functionality, leading to the need for professional automotive repair services. Vehicle paint repair and bodywork may also be necessary if the accident has caused visible damage to these areas, affecting both aesthetics and the overall structural integrity of the vehicle.

Restoring Cooling Efficiency: Step-by-Step AC System Reconstruction

After a rear-end collision, restoring the AC system’s cooling efficiency is a meticulous process that requires expertise and precision. Here’s a step-by-step guide for AC system reconstruction:

1. Safety First: Before beginning any repair work, ensure the vehicle is safe to work on, and all necessary safety protocols are followed. This includes wearing protective gear and using jack stands to secure the vehicle properly.

2. Diagnosis: The first step in AC system reconstruction is identifying the source of the problem. Technicians should check for leaks, damaged components, or corrosion that may have been caused by the collision. Using specialized tools, they can detect refrigerant levels, pressure, and any anomalies within the system.

3. Component Replacement: Depending on the damage, several components might need replacing. This could include the condenser, evaporator coils, fan motors, or the entire AC compressor unit. It’s crucial to use genuine replacement parts designed for optimal performance and compatibility with your vehicle make and model.

4. Refrigerant Recharge: After repairing or replacing damaged components, the refrigerant needs to be recharged. This step ensures the system can effectively cool the vehicle interior. Technicians carefully inject the correct amount of refrigerant into the system, following manufacturer guidelines.

5. Testing and Sealing: Once the AC system is reconstructed, thorough testing is essential. This involves cycling the system on and off to ensure proper cooling performance and pressure levels. Any leaks should be sealed to prevent future issues.

6. Optimization: To guarantee optimal cooling efficiency after repairs, consider regular maintenance checks. Fleet repair services often recommend periodic inspections to keep AC systems in top condition, ensuring they’re ready when you need them the most, especially during hot summer days for auto repair near me customers.

After a rear-end vehicle accident, proper assessment and repair of the AC system are crucial for restoring comfort and ensuring optimal cooling performance. Understanding the common components affected in such collisions is essential for effective AC system reconstruction. By following a systematic approach that includes assessing damage, identifying faulty parts, and meticulously rebuilding the AC system, professionals can effectively restore its cooling efficiency, providing drivers with a refreshing driving experience once again.