Safety sensor recalibration is crucial for modern camera systems in high-stakes industries like automotive repair, preventing errors, accidents, and costly repairs by ensuring precise obstacle detection and reliable data. Regular calibration schedules using structured procedures and tools maintain system reliability, reduce errors, and prolong equipment lifespan across diverse applications from autonomous vehicles to industrial automation.

Camera systems, integral to modern surveillance and automation, rely heavily on accurate safety sensor recalibration. This ensures their ability to accurately detect and respond to environmental changes, preventing accidents and enhancing operational efficiency. Understanding the recurring need for safety sensor recalibration and its significant impact on camera system performance is crucial. This article explores effective strategies for regular recalibration, emphasizing best practices to maintain optimal camera functionality and ensure worker safety in dynamic environments.

- Understanding Safety Sensor Recalibration Needs

- Impact of Incorrect Calibration on Camera Systems

- Effective Strategies for Regular Recalibration

Understanding Safety Sensor Recalibration Needs

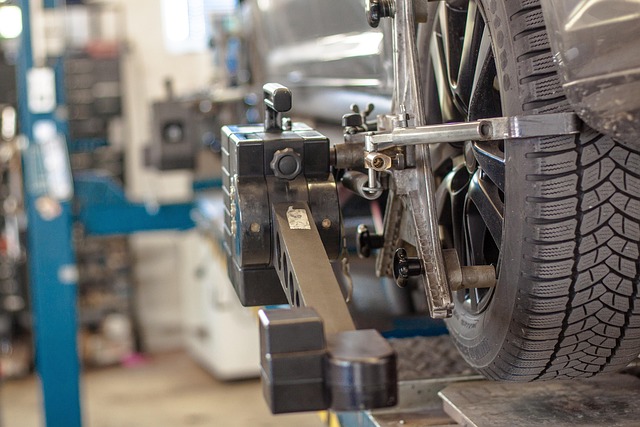

Accurate safety sensor recalibration is a fundamental aspect of modern camera systems, especially in industries where precision and safety are paramount. These sensors play a critical role in various applications, from autonomous vehicles to industrial automation, ensuring that machines and vehicles navigate their environment securely. In the context of vehicle paint repair or auto body repair facilities, where hail damage repair is a common occurrence, precise sensor calibration becomes even more vital. Any deviation in sensor readings can lead to inaccurate assessments and potential safety risks.

Regular recalibration is essential to account for environmental changes and wear over time. Sensor drift, caused by factors like temperature fluctuations, age, or external interference, can introduce errors into the system. By implementing a robust recalibration process, these issues are mitigated, ensuring that camera systems provide reliable data for decision-making processes. This is particularly crucial in high-stakes scenarios where errors could result in accidents or costly repairs, such as those involving hail damage to vehicles.

Impact of Incorrect Calibration on Camera Systems

The precision and reliability of camera systems heavily rely on accurate safety sensor recalibration. Incorrect calibration can lead to significant issues in various applications, from autonomous vehicles to industrial automation. When sensors are not properly calibrated, the data they provide becomes inconsistent and unreliable, causing potential hazards and inaccuracies in decision-making processes. For instance, in an autonomous vehicle, misaligned or improperly calibrated cameras might fail to detect obstacles accurately, increasing the risk of collisions and compromising passenger safety.

In a vehicle body shop or paintless dent repair facility, camera systems are crucial for accurate measurements and repairs. Incorrect calibration can result in flawed measurements, leading to poor fender repairs or other cosmetic issues. This not only impacts the quality of the final product but also wastes time and resources, delaying service times and potentially damaging customer satisfaction. Regular safety sensor recalibration is therefore an essential maintenance practice to ensure camera systems function optimally and contribute to safer, more efficient operations across industries.

Effective Strategies for Regular Recalibration

Regular recalibration of safety sensors is paramount for maintaining optimal camera system performance. Over time, environmental factors like dust, debris, and changes in lighting conditions can impact sensor accuracy. Implementing a structured calibration schedule ensures that these variations are accounted for, enhancing overall system reliability. During recalibration, it’s crucial to follow specific procedures recommended by the manufacturer, using precise tools and targets to ensure accurate adjustments.

For car repair shops offering collision repair services or specializing in car dent removal, establishing a rigorous sensor recalibration process is beneficial. By prioritizing this aspect, these workshops can deliver more precise camera-based inspections, ultimately improving the quality of their work. Regular maintenance not only minimizes errors but also extends the lifespan of both the camera systems and the vehicles they service.

Camera systems rely heavily on accurate safety sensor recalibration to ensure optimal performance and prevent potential hazards. By understanding the recurring need for this process, recognizing the significant impact of incorrect calibration, and adopting effective strategies for regular recalibration, users can maximize the reliability and efficiency of their camera systems in various applications. Regular safety sensor recalibration is a fundamental practice that guarantees the integrity and safety of operations dependent on these sophisticated technologies.