Cutting-edge technology in metropolitan collision repair enhances efficiency and precision, with laser measuring systems, CAD software, digital imaging, 3D scanning, robotic welding, cloud-based management, and real-time diagnostics revolutionizing shop operations. Advanced sensors, cameras, and integrated diagnostic systems detect even minor damage, reducing errors and turnaround times. Digital solutions like remote access to vehicle data benefit high-end brands and fleet managers, optimizing internal processes while delivering superior customer experiences.

In the dynamic landscape of metropolitan collision repair, shops are no longer relying on traditional methods. Advanced tools and technology have revolutionized the industry, offering efficient repairs, enhanced safety, and precision. This article explores cutting-edge technologies that streamline workflows, smart tools improving safety standards, and digital solutions transforming how metropolitan collision repair shops operate. Discover how these innovations contribute to faster turnarounds, higher quality work, and a safer environment for technicians and customers alike.

- Cutting-Edge Technology for Efficient Repairs

- Smart Tools: Enhancing Safety and Precision

- Digital Solutions for Streamlined Workflows

Cutting-Edge Technology for Efficient Repairs

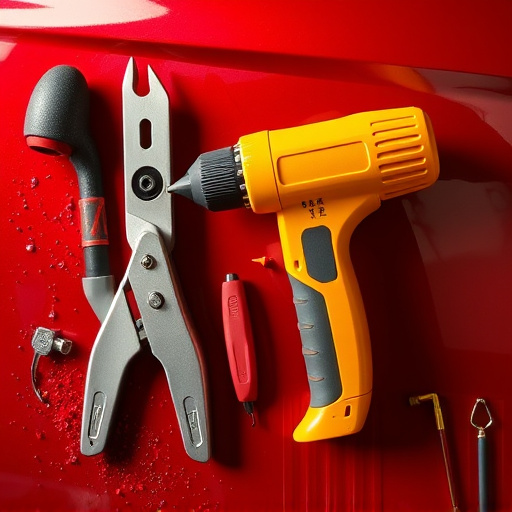

In the realm of metropolitan collision repair, cutting-edge technology is revolutionizing the way shops conduct vehicle body repair. Advanced tools and software enable efficient and precise work, ensuring that every fix is both sturdy and swift. These innovations range from laser measuring systems that capture exact dimensions, minimizing errors in auto body work, to computer-aided design (CAD) programs that streamline the creation of customized parts, enhancing the overall collision repair process.

With digital imaging and 3D scanning technologies, collision repair shops can now analyze damage with unprecedented accuracy. This enables them to provide more accurate estimates and faster turnaround times. Moreover, robotic welding systems offer enhanced precision and consistency, leading to stronger welds that contribute to longer-lasting vehicle body repairs. These technological advances not only elevate the standard of automotive body work but also cater to the demanding needs of metropolitan collision repair shops, ensuring that vehicles are restored to their pre-incident condition in no time.

Smart Tools: Enhancing Safety and Precision

In the realm of metropolitan collision repair, the integration of smart tools is transforming the way shops conduct business. These innovative technologies are designed to enhance safety and precision in every aspect of the repair process, from initial assessments to final inspections. For instance, advanced sensors and cameras enable technicians to detect even subtle car scratches or vehicle dents with remarkable accuracy, ensuring no damage goes unnoticed.

Furthermore, smart tools facilitate more efficient fleet repair services. Integrated diagnostic systems quickly identify issues within a vehicle’s complex network of components, streamlining the troubleshooting process. This not only reduces the time required for repairs but also minimizes the risk of human error. As a result, metropolitan collision repair shops are able to deliver superior quality services, catering to both individual car owners and large-scale fleet managers alike, while maintaining the highest standards of safety and precision.

Digital Solutions for Streamlined Workflows

In today’s digital era, metropolitan collision repair shops are embracing advanced tools and technologies to streamline workflows and enhance efficiency. From cloud-based management systems to real-time diagnostics software, these innovations allow for quicker turnaround times and improved accuracy in car bodywork repairs. For instance, digital solutions like remote access to vehicle data enable technicians to diagnose issues more effectively, even before physically examining the vehicle. This technology is particularly beneficial for high-end brands such as Mercedes Benz repair workshops, where precise and swift service is paramount.

Furthermore, fleet repair services benefit immensely from these digital transformations. Integrated software platforms facilitate better inventory management, scheduling, and communication with clients. By leveraging these advanced tools, metropolitan collision repair shops not only optimize their internal processes but also offer superior customer experiences, catering to the diverse needs of modern vehicle owners and commercial fleet operators alike.

In today’s digital era, metropolitan collision repair shops are revolutionizing their operations with advanced tools. From cutting-edge technology that speeds up repairs to smart tools enhancing safety and precision, these innovations are transforming the landscape of automotive maintenance. Digital solutions also streamline workflows, making processes more efficient and effective. As these advancements continue to evolve, metropolitan collision repair professionals are better equipped to provide top-notch services, ensuring faster turnarounds and higher customer satisfaction.