Resistance spot welding is a specialized automotive technique using electrical current for precise, strong metal bonding. Its precision, efficiency, strength, and versatility make it ideal for intricate body repairs, minimizing heat impact on surrounding areas. Preferred in the auto industry for its quality, speed, and eco-friendliness, it's crucial for skilled technicians achieving clean, high-quality welds through optimal parameter control and surface preparation.

Resistance spot welding is a pivotal technology in modern vehicle repairs, offering precise and strong welds. This article delves into the intricacies of this process, highlighting its significance in the automotive industry. We’ll explore how it works, its numerous advantages, and common applications from structural repairs to body panel joining. Discover best practices for optimal results, making resistance spot welding an indispensable tool for efficient and reliable car maintenance.

- Understanding Resistance Spot Welding Technology

- Advantages of Using Resistance Spot Welding in Vehicle Repairs

- Common Applications and Best Practices for Spot Welding Cars

Understanding Resistance Spot Welding Technology

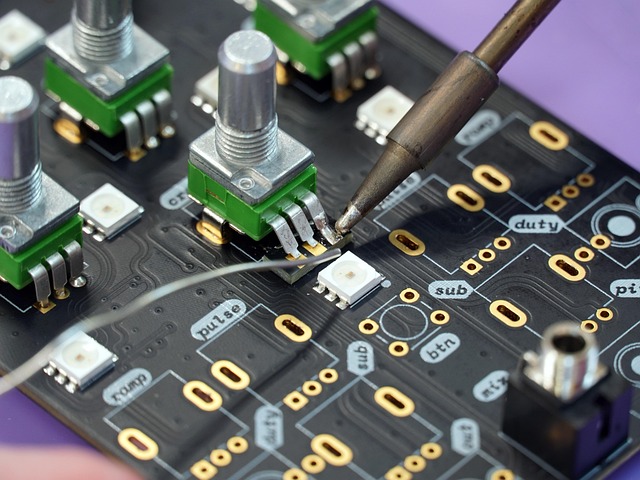

Resistance spot welding is a specialized technique used in automotive manufacturing and repair, offering precise and strong bonding of metal components. This process involves applying a controlled electrical current between two conductive surfaces, causing resistance heating and subsequent fusion. The technology is renowned for its ability to create robust welds, making it an indispensable method in the auto industry, particularly for intricate auto body repairs and assembly.

Understanding how this welding technique works is key to appreciating its benefits in auto maintenance. By focusing energy at a specific point, it minimizes heat input to surrounding areas, preserving nearby materials and components. This precision is especially valuable in delicate auto body services, where structural integrity must be maintained while making repairs. Resistance spot welding’s efficiency, strength, and versatility make it an attractive solution for various automotive applications, ensuring superior quality and durability in vehicle repairs.

Advantages of Using Resistance Spot Welding in Vehicle Repairs

Resistance spot welding offers numerous advantages in vehicle repairs, making it a preferred method in the automotive industry. One key benefit is its precision and strength; this technique allows for exact welds with high structural integrity, ensuring the repaired area meets or exceeds original equipment quality. This precision is particularly valuable when dealing with complex vehicle designs, where maintaining the vehicle’s structural integrity is crucial.

Furthermore, resistance spot welding is an efficient process that reduces repair times compared to traditional methods. Its non-invasive nature minimizes metal distortion and damage during welding, which is advantageous in automotive collision repair and vehicle body repair scenarios. This efficiency translates to cost savings for both repair shops and vehicle owners, making it an eco-friendly and economically viable option for auto maintenance.

Common Applications and Best Practices for Spot Welding Cars

Resistance spot welding is a prevalent technique within the automotive industry, offering precision and strength for various repairs. This method is commonly employed in auto repair services and car body shops to join metal components, making it an indispensable tool for skilled technicians. From panel replacements to structural repairs, resistance spot welding ensures robust connections, enhancing the overall integrity of vehicles.

Best practices dictate that welders maintain optimal parameters, including temperature and pressure, to achieve clean, high-quality welds. Consistent practice and training are essential for professionals in car body shops to master this skill, ensuring minimal distortion and maximizing the structural soundness of repaired vehicles. Moreover, proper preparation of the metal surface is vital, involving degreasing and deburring to create a suitable bond for resistance spot welding, thus addressing issues like scratch repair effectively.

Resistance spot welding has established itself as a fundamental technique in vehicle repairs, offering numerous advantages over traditional methods. Its precision, efficiency, and strength make it an indispensable tool for auto body shops. By understanding this technology and implementing best practices, professionals can ensure high-quality, durable repairs that meet modern automotive standards. Resistance spot welding continues to be a game-changer in the industry, revolutionizing how we approach vehicle maintenance and repair.