Spot welding systems are essential for metal joining in industries like automotive, manufacturing, and construction, offering precise, efficient bonds for repairs and restorations. These systems use power sources, electrodes, and control units to focus energy, melt, and intermix materials, creating strong joints quickly. Auto repair, dent repair, and fender bender fixes benefit from spot welding's versatility, quality assurance, and operator-friendly controls.

Spot welding systems are essential in manufacturing, offering precise and efficient metal joining. This article demystifies the process, guiding you through its fundamentals. We’ll explore what spot welding is, dissect the key components of these systems, and understand their operation. From automotive to electronics, spot welding systems play a vital role, ensuring strength and reliability in various industries. Get ready to discover the science behind this powerful technique.

What is Spot Welding?

Spot welding is a highly efficient and precise method of joining metal components, commonly used in various industries, including automotive, manufacturing, and construction. It involves applying concentrated heat to specific points on the metal surfaces, causing them to melt and fuse together. This process creates strong, permanent bonds, making spot welding an indispensable technique for many spot welding systems.

In the context of vehicle repair services and fleet repair services, spot welding is particularly valuable for repairing or replacing damaged panels in cars, trucks, and other vehicles. It allows skilled technicians to quickly and accurately rejoin metal bodies, ensuring structural integrity and a seamless finish, much like in car restoration projects where precision and quality are paramount.

Components of a Spot Welding System

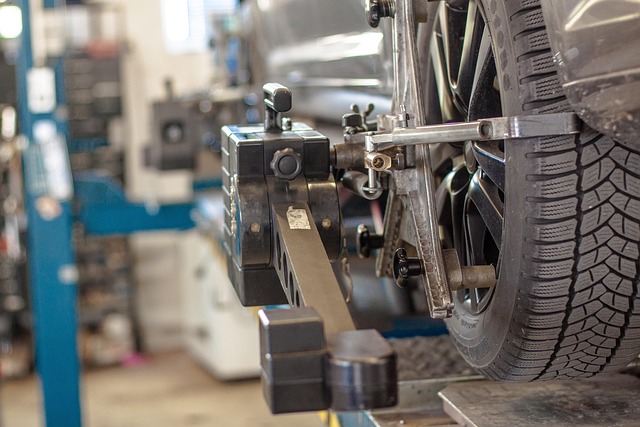

Spot welding systems are integral to various industrial applications, especially in the automotive industry for vehicle dent repair and fender bender repairs. These systems consist of several key components that work together to create strong, precise welds. The primary elements include a power source, such as an AC or DC power supply, which provides the necessary energy to melt and fuse metals. This is coupled with electrodes, typically made of copper or tungsten, that conduct the electrical current and focus it on the specific point of contact.

A control unit acts as the brain of the spot welding system, regulating the flow of electricity and timing to ensure optimal welds. It allows for precise control over parameters like current, voltage, and pulse duration, which are crucial for different metal types and joint designs. Additionally, these systems often incorporate a foot pedal or trigger mechanism for operator control, enabling them to initiate the welding process with precision, making auto repair near me tasks more efficient and effective.

How Spot Welding Systems Work

Spot welding systems are designed to create strong, precise bonds between metal sheets by focusing a concentrated beam of energy onto specific points of contact. This process involves passing an electric current through a pair of electrodes pressed against the metal, causing them to melt and intermix, forming a solid joint. The key advantage lies in its efficiency; spot welding allows for quick assembly and repair in auto body repair, automotive restoration, and even vehicle dent repair scenarios.

These systems are versatile, capable of handling various materials and thicknesses while ensuring consistent quality. By controlling factors like current, time, and pressure, operators can achieve welds that meet specific strength and aesthetic requirements. This level of precision makes spot welding an indispensable technique in industries where structural integrity and visual appeal are paramount.

Spot welding systems are versatile and efficient tools for joining metal components, making them indispensable in various industries. By understanding the fundamental concepts, including the key components and working principles, users can optimize their welding processes. This knowledge ensures precise, strong, and reliable connections, contributing to the overall quality of manufacturing outcomes. Whether for automotive, electronics, or construction applications, spot welding remains a game-changer, offering both precision and productivity.