Mercedes vehicles rely on advanced sensors and adjustments for peak performance and precision engineering. Regular calibration maintenance prevents system lag and ensures critical components like engine efficiency and tire pressure sensors operate optimally, extending component lifespan and enhancing safety features' reliability. Outdated or damaged sensors lead to costly repairs and decreased resale value; thus, proactive Mercedes sensor adjustment is vital for both new car maintenance and classic car restoration.

Mercedes vehicles rely on a sophisticated network of sensors for optimal performance. Regular Mercedes sensor adjustment is crucial to maintaining system efficiency, preventing lag, and minimizing calibration drift. This article explores the intricate mechanisms behind Mercedes sensor adjustment, highlighting its benefits and addressing common causes of system issues. By understanding these principles, owners can ensure their Mercedes runs smoothly and reliably.

- Understanding Mercedes Sensor Adjustment Mechanisms

- Benefits of Regular Calibration Maintenance

- Common Causes of System Lag and Drift Prevention

Understanding Mercedes Sensor Adjustment Mechanisms

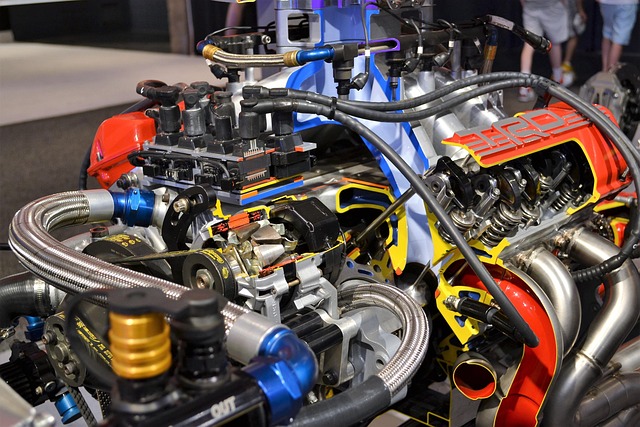

Mercedes vehicles are renowned for their advanced technology and precision engineering, and a key component to this success is the sophisticated sensor adjustment mechanisms employed across their systems. These sensors play a vital role in monitoring various aspects of the vehicle’s performance, from engine efficiency to tire pressure. Regular Mercedes sensor adjustment ensures these critical components operate at optimal levels, preventing system lag and calibration drift.

Through a combination of mechanical adjustments and digital calibrations, Mercedes engineers fine-tune these sensors to deliver accurate and reliable data. This process is particularly crucial in modern vehicles with complex onboard computers that rely on sensor feedback for everything from fuel injection to anti-lock braking systems (ABS). Maintaining proper sensor adjustment not only enhances vehicle performance but also contributes to the longevity of components, making it an essential aspect of both new car maintenance and classic car restoration, ensuring these mechanical marvels continue to run smoothly throughout their service lives, whether it’s a state-of-the-art model or a beloved vintage ride needing auto body repairs.

Benefits of Regular Calibration Maintenance

Regular calibration maintenance for Mercedes sensor adjustment is a critical aspect of vehicle ownership that often goes overlooked until issues arise. By proactively addressing sensor calibration, car owners can enjoy several significant benefits. Firstly, it helps to maintain the accuracy and reliability of various onboard systems, ensuring optimal performance and safety features. For instance, sensors play a pivotal role in anti-lock braking systems (ABS), traction control, and engine management, among others. Any drift or calibration error can lead to inconsistent responses from these systems, potentially compromising driving safety.

Moreover, regular sensor adjustment prevents issues related to hail damage repair or collision damage repair, which could otherwise arise due to inaccurate readings. Even minor dents or scratches affecting the vehicle’s body can impact sensor functionality over time, leading to false alerts or incorrect system behavior. By keeping sensors calibrated, car owners can avoid unnecessary repairs and costly collision damage repair processes. This proactive approach not only enhances the overall driving experience but also contributes to maintaining the vehicle’s resale value by ensuring its systems are in peak condition.

Common Causes of System Lag and Drift Prevention

In the realm of luxury vehicle repair, system lag and calibration drift are common issues that can significantly impact performance. These problems often arise from various factors such as sensor malfunctions, outdated calibrations, or environmental interference. Mercedes sensors, being integral components in modern car bodywork services, require regular adjustment to maintain optimal efficiency. One of the primary causes of system lag is outdated or damaged sensors, which can lead to inaccurate readings and delayed responses. Calibration drift, on the other hand, occurs over time as sensors lose precision due to wear and tear or exposure to extreme conditions.

Preventing these issues requires proactive measures. Regular Mercedes sensor adjustment ensures that each component is functioning at its best, minimizing lag and drift. Fleet repair services often emphasize this maintenance step to maintain high performance standards across their vehicle fleets. By keeping sensors calibrated and well-maintained, car bodywork services can prevent costly breakdowns and enhance overall vehicle reliability. This proactive approach not only extends the life of the sensors but also ensures the smooth operation of the entire system, contributing to a safer and more efficient driving experience.

Mercedes sensor adjustment is a critical process that ensures the vehicle’s advanced systems operate with precision. By regularly calibrating sensors, drivers can prevent system lag and calibration drift, leading to improved performance and safety. Understanding the mechanisms behind these adjustments and addressing common causes of issues allows owners to keep their Mercedes vehicles running optimally. This proactive approach to maintenance is key to maximizing the benefits of cutting-edge automotive technology.