Tesla OEM parts replacement ensures vehicle safety and performance by providing precise engineering and seamless integration with the vehicle's frame. Structural adhesives offer advantages over traditional methods, streamlining workflows, reducing costs, and promoting lightweight construction. Choosing the right adhesive for Tesla OEM parts is crucial to withstand stress, maintain clarity, and ensure compatibility with modern vehicle materials and environmental factors.

Tesla vehicles, renowned for their cutting-edge technology, rely on Original Equipment Manufacturer (OEM) parts for structural integrity. When replacing these critical components, using structural adhesives offers significant advantages over traditional methods. This article explores the importance of Tesla OEM parts in vehicle structure and highlights how adhesive solutions enhance safety and performance. We delve into choosing the right adhesive, considering compatibility and performance to ensure optimal results in Tesla OEM parts replacement.

- Understanding Tesla OEM Parts and Their Role in Vehicle Structure

- Advantages of Using Structural Adhesives for Replacement

- Choosing the Right Adhesive: Compatibility and Performance Considerations

Understanding Tesla OEM Parts and Their Role in Vehicle Structure

Tesla Original Equipment Manufacturer (OEM) parts play a pivotal role in maintaining and repairing vehicle structures. These parts are designed to meet Tesla’s stringent quality standards, ensuring optimal performance and safety. When it comes to replacing structural components after a car collision repair or addressing vehicle bodywork issues, using genuine Tesla OEM parts is essential. They are precisely engineered to fit and align with the vehicle’s frame, offering both strength and durability.

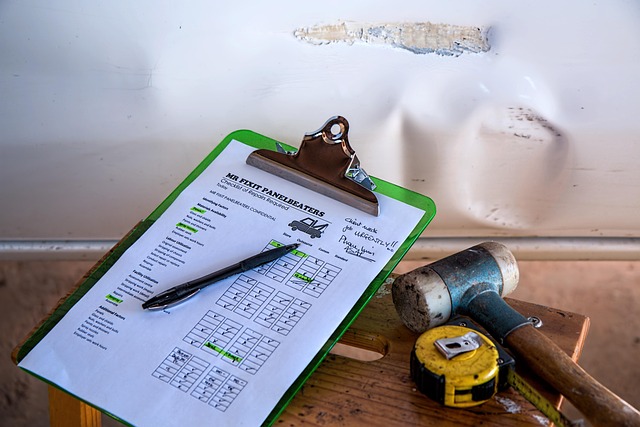

Compared to aftermarket alternatives, Tesla OEM parts offer enhanced compatibility and longevity. In the event of car dent removal or more complex structural repairs, relying on these original components guarantees a seamless integration into the vehicle’s existing design and mechanics. This not only preserves the car’s aesthetic appeal but also ensures the structural integrity necessary for safe driving, making Tesla OEM parts replacement a crucial consideration in modern automotive care.

Advantages of Using Structural Adhesives for Replacement

Using structural adhesives for Tesla OEM parts replacement offers several significant advantages over traditional fastening methods, such as welding or bolting. Firstly, adhesives provide a seamless bond, ensuring structural integrity and a robust connection between components, which is crucial for maintaining the vehicle’s safety and performance. This method is particularly beneficial when replacing damaged or worn-out parts, as it allows for precise alignment and reproduction of the original manufacturer’s design, resulting in superior fit and finish.

In the context of collision repair shops and auto body repairs, structural adhesives offer a more efficient and cost-effective solution. They eliminate the need for extensive metal fabrication or complex welding processes, streamlining the repair workflow and reducing labor costs. Moreover, adhesives promote lightweight construction, contributing to better fuel efficiency and overall vehicle performance, which is in line with Tesla’s commitment to innovation and sustainability in auto body shops.

Choosing the Right Adhesive: Compatibility and Performance Considerations

When undertaking Tesla OEM parts replacement, especially for structural components, selecting the appropriate adhesive is paramount to ensure both safety and longevity. The right adhesive must offer superior bonding strength while being compatible with the materials used in modern vehicles, such as advanced composites and metals. Compatibility considerations extend beyond just material pairs; environmental factors like temperature and humidity, as well as exposure to chemicals and UV light, should also be accounted for.

Performance is another critical aspect. Adhesives must withstand significant stress and strain, particularly in areas subject to impact or vibration. For auto glass replacement or other high-visibility repairs, clear strength and optical quality are essential. Auto body shops specializing in Tesla OEM parts replacement should therefore choose adhesives designed for specific structural applications, ensuring they meet the demanding requirements of modern vehicle construction and offering consistent, reliable performance across various auto body services.

The efficient use of structural adhesives in Tesla OEM parts replacement offers a robust, lightweight solution that enhances vehicle performance and safety. By understanding the critical role of these parts and selecting the right adhesive, manufacturers can ensure long-lasting repairs, improving overall vehicle integrity. This innovative approach to Tesla OEM parts replacement is poised to revolutionize the automotive industry, setting new standards for strength, durability, and environmental sustainability.