The automotive industry shifts towards eco-friendly B-pillar replacement, driven by sustainability goals and consumer demand. Using recycled materials, efficient disassembly techniques, and advanced manufacturing, body shops minimize environmental impact while promoting a circular economy. This aligns with global efforts to reduce waste in car collision repair, optimizing processes for greener mobility.

In the pursuit of sustainable mobility, understanding and mitigating the environmental impact of B-pillar replacement is paramount. This article delves into crucial aspects of eco-friendly transformations within the automotive industry’s essential structural element. We explore how adopting sustainable materials can significantly reduce environmental footprint while discussing strategies to optimize manufacturing processes for a greener future. By focusing on these key areas, we aim to highlight the potential for environmentally conscious B-pillar replacement solutions.

- Understanding B-Pillar Replacement Impact

- Sustainable Materials for Eco-Friendly Alternatives

- Optimizing Manufacturing Processes for Reduced Carbon Footprint

Understanding B-Pillar Replacement Impact

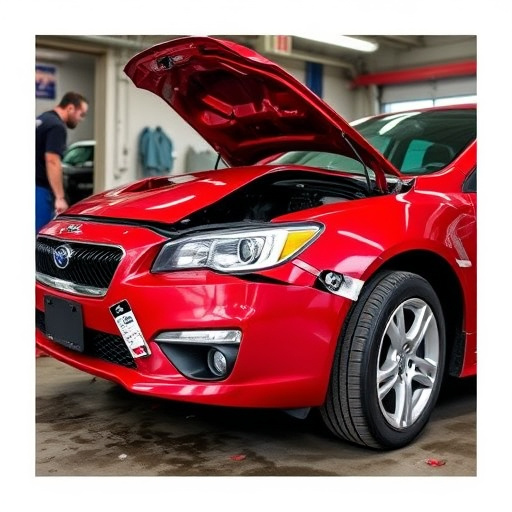

The concept of B-pillar replacement in automotive body shops has gained significant attention due to its potential environmental impact and contribution to sustainable car collision repair practices. This process involves the careful disassembly, recycling, and subsequent replacement of a vehicle’s structural pillar—a critical component for passenger safety. Understanding the ecological considerations is paramount as it aligns with global efforts to reduce waste and promote eco-friendly car body restoration techniques.

B-pillars, often hidden within the vehicle’s design, play a vital role in maintaining cabin integrity during accidents. Replacing them requires a strategic approach to minimize environmental consequences. Automotive body shops now embrace eco-conscious practices by utilizing recycled materials, implementing efficient disassembly techniques, and ensuring proper disposal of old pillars. This not only reduces the carbon footprint associated with car collision repair but also fosters a circular economy, where resources are repurposed and reused in the automotive manufacturing process, promoting a more sustainable future for car body restoration.

Sustainable Materials for Eco-Friendly Alternatives

In the realm of B-pillar replacement, the shift towards sustainability has sparked a revolution in automotive manufacturing. Eco-conscious consumers and regulatory pressures are driving the demand for environmentally friendly alternatives to traditional materials. One key area of focus is the use of sustainable materials in car paint repair and autobody repairs. These innovative solutions aim to reduce the environmental impact associated with frame straightening processes, which have historically relied on resource-intensive practices.

By embracing eco-friendly options, manufacturers can contribute to a greener landscape. Biodegradable compounds and recycled content are increasingly integrated into car paint formulations, minimizing waste and pollution. Moreover, advanced manufacturing techniques enable precise repairs, reducing the need for extensive frame straightening—a process that consumes significant energy and generates greenhouse gas emissions. This shift towards sustainable materials not only benefits the environment but also aligns with consumer expectations for greener products, ultimately shaping a more eco-conscious automotive industry.

Optimizing Manufacturing Processes for Reduced Carbon Footprint

In the quest for sustainable mobility, optimizing manufacturing processes is a key aspect when it comes to B-pillar replacement. This involves exploring eco-friendly materials and techniques to minimize the carbon footprint associated with vehicle production. By adopting innovative approaches, such as using recycled or bio-based materials in car body repair and paint applications, manufacturers can significantly reduce emissions and waste generation.

Additionally, refining manufacturing methods through digital technologies enables precise and efficient operations. This includes implementing industry 4.0 principles, like automation and robotics, to streamline vehicle repair processes, ensuring faster turnaround times while also decreasing energy consumption. These strategies not only support sustainable practices but also contribute to the overall cost-effectiveness of B-pillar replacement, making it a viable and responsible choice in the automotive industry.

In conclusion, considering environmental factors in B-pillar replacement is no longer an option but a necessity. By understanding the impact, exploring sustainable materials, and optimizing manufacturing processes, we can significantly reduce the carbon footprint of this essential automotive component. Embracing eco-friendly alternatives not only benefits the planet but also drives innovation and ensures a greener future for the automotive industry.