Frame rail replacement, critical for car safety and stability, demands specialized tools and expert knowledge. It involves a detailed process from inspection to alignment, requiring strict safety protocols and protective gear in professional body shops. This meticulous approach ensures structural integrity, preventing further damage, especially during concurrent tasks like dent repair.

Frame rail replacement is a critical procedure for vehicle restoration, but it demands meticulous safety protocols. This comprehensive guide explores the essential steps and best practices for a successful and safe frame rail replacement. From understanding the frame rail structure and associated risks to equipping yourself with proper safety gear, we cover it all. We then walk you through a detailed, step-by-step process, ensuring your work meets industry standards.

- Understanding Frame Rail Structure and Risks

- Safety Gear and Preparation Checklist

- Step-by-Step Replacement Process: Best Practices Ensured

Understanding Frame Rail Structure and Risks

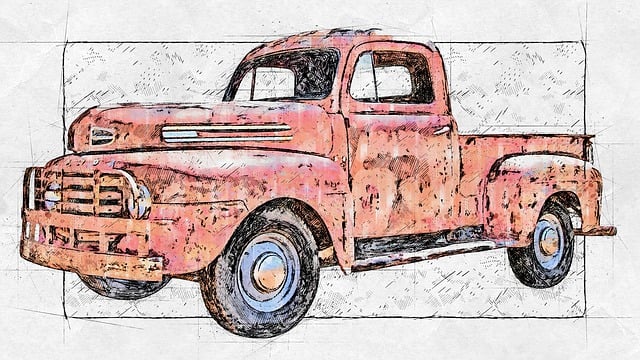

Understanding the frame rail structure is paramount when considering a frame rail replacement. The frame rail, often referred to as the backbone of a vehicle, is a critical component that supports the car’s weight and provides structural integrity. In many vehicles, especially luxury brands like Mercedes Benz repair, the frame rail is not just a single beam but a network of interconnected rails that form a robust framework. When performing a frame rail replacement, it’s crucial to identify these specific sections and ensure proper alignment for optimal vehicle performance and safety.

Risks associated with frame rail replacement cannot be overlooked. Improper installation can lead to structural weaknesses, compromising the car’s overall stability and safety features. In a car body shop, technicians must adhere to strict protocols, using specialized tools and equipment to measure, cut, and fit new rails accurately. Moreover, for vehicles with complex body designs or significant damage, such as those requiring vehicle dent repair, replacing frame rails may involve intricate processes that demand expert knowledge and precision to avoid further complications.

Safety Gear and Preparation Checklist

Before beginning any frame rail replacement, ensuring safety should be the top priority for every vehicle restoration or car repair service enthusiast. The process involves intricate metalwork and manipulation of heavy components, making proper protection essential. Safety gear includes thick, protective gloves, safety goggles to shield against debris and sparks, and a high-quality respirator mask to filter out harmful dust and fumes. For more advanced procedures, a full-body harness connected to a secure point above can provide an extra layer of protection.

A comprehensive preparation checklist is also vital. This should include gathering all necessary tools and parts, ensuring proper lighting for clear visibility, and setting up a stable workbench or platform to support the vehicle safely during the frame rail replacement process. Double-checking that all safety protocols are in place and understood by everyone involved is crucial before initiating any work on your vehicle repair services project.

Step-by-Step Replacement Process: Best Practices Ensured

Frame rail replacement is a critical process in collision repair and vehicle restoration, demanding meticulous precision to ensure structural integrity. The step-by-step procedure involves several best practices designed to safeguard both the vehicle and the technicians. First, thoroughly inspect the existing frame rails for damage, corrosion, or deformity, using specialized tools to measure and identify any irregularities. This critical assessment guides the replacement strategy, dictating the extent of the work required.

Next, carefully disassemble the affected components, taking care to mark and document each part for proper reassembly later. With safety as a paramount concern, technicians should don appropriate personal protective equipment (PPE) before beginning the removal process. Once the old rails are safely extracted, new frame rails are meticulously aligned, ensuring they conform to the vehicle’s specifications. The replacement rails are then securely installed using industry-standard fasteners, subjected to rigorous testing to verify their stability and alignment before any final touches are applied. This meticulous approach ensures not just a functional repair but also the longevity of the vehicle in the hands of a competent vehicle body shop.

Frame rail replacement is a complex task that requires meticulous planning, proper safety gear, and adherence to best practices. By understanding the frame rail structure, preparing adequately, and following a structured process, you can ensure a safe and successful frame rail replacement. Remember to always prioritize safety and consider these protocols as a foundation for your project’s success.