The adoption of electronic measuring equipment has revolutionized automotive manufacturing, shifting from manual, imprecise methods to a new standard of meticulous accuracy. This technology ensures consistent and precise dimensions, streamlining assembly lines and bodywork for enhanced efficiency and quality. As a result, it enables the realization of innovative vehicle designs previously deemed unfeasible and transforms repair processes, reducing errors, expediting repairs, and improving customer satisfaction. Ultimately, electronic measuring equipment enhances auto frame repair and restoration services, leading to faster turnaround times and safer, more reliable vehicles that meet modern consumers' demands for convenience.

The auto industry has undergone a silent revolution, driven by the adoption of electronic measuring equipment. This technology has transformed manufacturing processes, enhancing precision and efficiency. From the shop floor to quality control, advanced electronic tools have set new standards for accuracy, pushing safety margins higher. As we look ahead, AI, IoT, and automation are poised to reshape vehicle design, customization, and sustainability, continuing the evolution of electronic measuring equipment’s pivotal role in the industry’s future.

- The Evolution of Precision: How Electronic Measuring Equipment Revolutionized Auto Manufacturing

- – The shift from manual to electronic measuring tools

- – Increased accuracy and efficiency in production processes

The Evolution of Precision: How Electronic Measuring Equipment Revolutionized Auto Manufacturing

The evolution of precision in auto manufacturing is directly tied to the advent and progression of electronic measuring equipment. What was once a realm dominated by rough approximations and manual measurements is now an era characterized by meticulous accuracy and advanced technology. Electronic measuring tools have revolutionized the way automakers design, manufacture, and service vehicles, driving significant improvements in quality and efficiency.

Gone are the days when auto repair shops relied heavily on human eye estimates for vehicle body repair and bodywork. Modern electronic measuring equipment ensures consistent and precise dimensions, enabling more accurate assembly lines and meticulous auto bodywork. This technological shift has not only enhanced the overall precision of auto manufacturing but also allowed for innovative designs that were previously unattainable due to limitations in measurement accuracy.

– The shift from manual to electronic measuring tools

The auto industry has witnessed a profound transformation over the years, and one of the key drivers behind this change is the shift from manual to electronic measuring equipment. Historically, car bodywork services relied heavily on skilled technicians who used their hands, eyes, and traditional tools to measure and assess damage or alterations. However, with advancements in technology, vehicle paint repair and car body restoration processes have become more precise and efficient.

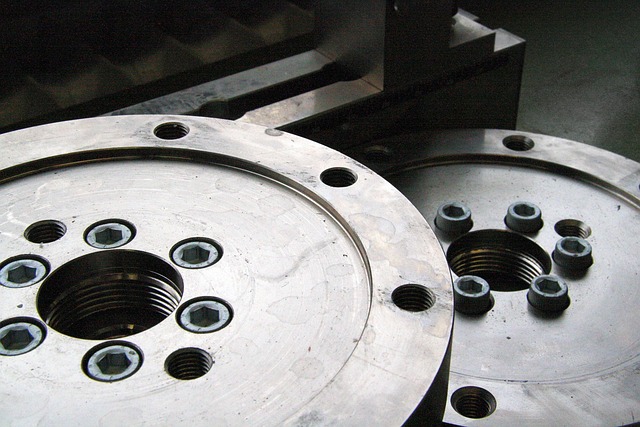

Electronic measuring equipment offers a range of benefits that have revolutionized the way auto professionals work. These tools provide accurate measurements, ensuring minimal errors during repairs or modifications. For example, digital measuring tapes and 3D scanning systems enable detailed inspections of car bodies, facilitating more effective damage assessment. This shift has not only improved the quality of car bodywork services but also enabled faster turnaround times for vehicle paint repair and restoration projects, ultimately enhancing customer satisfaction.

– Increased accuracy and efficiency in production processes

The integration of electronic measuring equipment into the automotive industry has revolutionized manufacturing processes, marking a significant shift from traditional manual methods. This technology brings unprecedented accuracy and efficiency to various stages of production. With advanced sensors and tools, manufacturers can now measure and analyze critical dimensions, angles, and tolerances with remarkable precision. As a result, components are produced with higher consistency, reducing the occurrence of defects and improving overall quality control.

Moreover, electronic measuring equipment plays a pivotal role in streamlining auto frame repair and vehicle restoration services. In the past, manual measurements were prone to human error, but now, specialized tools enable technicians to accurately assess damage, ensuring precise repairs. This not only expedites the restoration process but also enhances the final outcome, making vehicles safer and more reliable on the road. The increased efficiency has allowed for faster turnaround times in vehicle repair services, catering to modern consumers’ demands for convenience and timely solutions.

Electronic measuring equipment has undeniably revolutionized the auto industry, driving precision and efficiency to unprecedented heights. By replacing manual methods with advanced digital technologies, manufacturers can achieve remarkable accuracy in every stage of production. This transformation not only streamlines processes but also paves the way for innovative designs and higher-quality vehicles. As technology continues to evolve, we can expect even greater integration of electronic measuring equipment, further shaping the future of automotive manufacturing.