Mercedes aluminum welding is a specialized technique using advanced equipment and methods to fuse aluminum components, preserving structural integrity and lightweight design philosophy of Mercedes vehicles after damage. Key differences include specific tools, controlled conditions, and precise manipulation in impact zones, enhancing safety and structural stability without added weight. This modern approach revolutionizes auto body repairs, offering robust, authentic, and durable solutions for both new and classic Mercedes vehicles.

Mercedes aluminum welding is a precision art crucial for repairing impact zones and reinforcing the load path in automotive structures. This advanced technique, unique to Mercedes-Benz’s manufacturing process, offers unparalleled strength and lightweight benefits. In this article, we explore the intricate world of Mercedes aluminum welding, its application in critical repair areas, and how it ensures the integrity and safety of these iconic vehicles. Uncover the secrets behind this game-changing technology.

- Understanding Mercedes Aluminum Welding Techniques

- Impact Zones: Where Precision Meets Repair

- Load Path Repairs: Strengthening the Structural Backbone

Understanding Mercedes Aluminum Welding Techniques

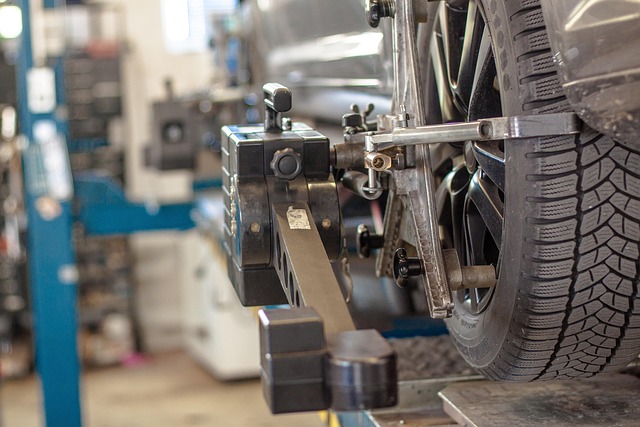

Mercedes aluminum welding is a specialized technique that plays a crucial role in repairing impact zones and load paths on Mercedes vehicles. This process involves fusing aluminum components together with precision and strength, ensuring structural integrity post-collision or damage. Auto repair shops and collision centers equipped with advanced welding equipment and trained technicians can perform this intricate work effectively.

The techniques employed in Mercedes aluminum welding differ from traditional metal welding methods due to the unique properties of aluminum. It often includes using specific types of welding guns, flux core wires, and controlled ambient conditions to prevent oxidation and ensure a strong bond. This specialized knowledge is vital when repairing fender benders or more significant damage, as it helps restore the vehicle’s safety and structural stability without compromising its lightweight design philosophy.

Impact Zones: Where Precision Meets Repair

In the intricate world of automotive repairs, especially for high-performance vehicles like Mercedes, understanding impact zones is paramount. These critical areas, often subjected to intense forces during collisions or accidents, demand precise and expert intervention. Here’s where Mercedes aluminum welding steps into the spotlight as a game-changer in vehicle repair services.

When it comes to repairing load paths and impact zones, an auto body shop must possess the skill to manipulate metal with finesse. Aluminum, known for its lightweight yet sturdy nature, requires specialized techniques during the welding process. This is especially true for Mercedes vehicles, renowned for their advanced engineering and precision design. Skilled technicians employ these techniques to ensure car body repair that not only restores structural integrity but also maintains the vehicle’s original aesthetic appeal, a crucial aspect in the auto body repair industry.

Load Path Repairs: Strengthening the Structural Backbone

Mercedes aluminum welding plays a pivotal role in ensuring robust Load Path Repairs, which are essential for enhancing the structural integrity of vehicles, especially in impact zones. When a vehicle sustains damage, whether from an accident or other impacts, it’s crucial to address not just visible dents but also the underlying structural components that carry the load during movement. Auto body repairs that involve Mercedes aluminum welding offer a superior solution compared to traditional methods for several reasons.

Aluminum is inherently lightweight yet incredibly strong, making it ideal for modern vehicle design. Skilled technicians can utilize this metal in intricate designs, ensuring strength and rigidity without adding excessive weight. This is particularly beneficial in impact zones where the focus should be on maintaining the structural backbone of the vehicle. Effective load path repairs through Mercedes aluminum welding not only strengthen these areas but also contribute to a safer driving experience, preventing further damage or failure during subsequent impacts. For classic car restorers, this technique adds an extra layer of authenticity and durability to their meticulous work.

Mercedes aluminum welding is a game-changer in automotive repair, especially for impact zones and load path repairs. By leveraging advanced techniques, professionals can restore structural integrity with precision and strength. Whether addressing damaged areas or reinforcing critical components, Mercedes aluminum welding ensures long-lasting results, enhancing vehicle safety and performance. Understanding the unique properties of aluminum and its effective welding methods is key to taking full advantage of this innovative repair approach.