Mercedes blind spot sensors detect nearby vehicles in blind spots and alert drivers. Xentry Diagnostics validates and ensures optimal sensor alignment for effective obstacle detection, enhancing safety during lane changes and overtaking. Accurate alignment prevents accidents, especially on highways, maintaining a seamless driving experience and quality auto glass repair in Mercedes vehicles.

Mercedes-Benz has pioneered advanced driver assistance systems, including its Blind Spot Sensor (BSS) technology. This article delves into the critical aspect of maintaining optimal BSS alignment using Xentry diagnostics. By understanding the sensor’s functionality and leveraging specialized tools, technicians can ensure precise detection and mitigation of blind spot hazards. Regular testing and calibration procedures are essential for upholding safety standards and maximizing vehicle performance in today’s smart automotive landscape.

- Understanding Mercedes Blind Spot Sensor Functionality

- Xentry Diagnostics: Tools for Alignment Validation

- Ensuring Optimal Safety: Testing and Calibration Procedures

Understanding Mercedes Blind Spot Sensor Functionality

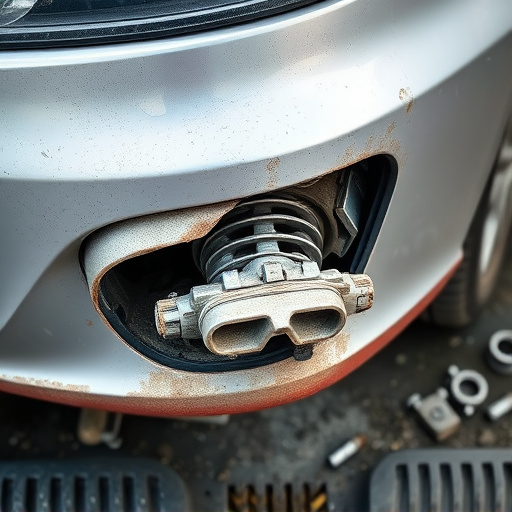

The Mercedes Blind Spot Sensor is a sophisticated piece of technology designed to enhance safety during lane changes and overtaking maneuvers. These sensors detect vehicles in the surrounding area, especially those within the blind spot zones that drivers may not immediately see. When a potential hazard is identified, the system alerts the driver through visual cues on the side mirrors or steering wheel display, ensuring they’re aware of nearby traffic before making a move.

Proper alignment of these sensors is crucial for their effectiveness. The Mercedes Blind Spot Sensor Alignment process involves calibrating and positioning the sensors accurately to ensure optimal detection range and accuracy. This ensures that the system provides reliable warnings, allowing drivers to take appropriate action, such as adjusting their lane position or slowing down, thereby preventing potential accidents, especially in heavy traffic or on highways where quick decisions can make a significant difference in safety.

Xentry Diagnostics: Tools for Alignment Validation

Xentry Diagnostics serves as a powerful tool for validating the alignment of Mercedes blind spot sensors. This advanced diagnostic system allows mechanics to accurately check the positioning and functionality of these critical safety components, ensuring they’re operating at peak performance. By leveraging Xentry’s precise capabilities, auto repair shops can effectively address any misalignments or defects in the car body repair process, directly impacting the overall safety and reliability of Mercedes vehicles.

Furthermore, Xentry Diagnostics streamlines the alignment validation process, making it more efficient for car repair shops. This not only saves time but also enhances accuracy, which is crucial when dealing with intricate systems like blind spot sensors. With proper alignment, these sensors can effectively detect potential hazards around the vehicle, contributing to a safer driving experience—a key aspect in maintaining top-notch auto glass repair quality and overall vehicle condition.

Ensuring Optimal Safety: Testing and Calibration Procedures

Ensuring Optimal Safety: Testing and Calibration Procedures

The Mercedes blind spot sensor alignment is a critical component for maintaining vehicle safety, especially during lane changes and overtaking maneuvers. Proper alignment ensures that these sensors accurately detect obstacles in the car’s blind spots, allowing drivers to make informed decisions to avoid potential collisions. Testing and calibration procedures play a vital role in upholding this safety standard. Through advanced diagnostic tools like Xentry, mechanics can meticulously evaluate each sensor’s performance, identifying any deviations from optimal positioning.

This process involves simulating real-world driving scenarios within the collision center environment. By generating signals that mimic other vehicles, technicians validate the sensor’s response time and accuracy. Any discrepancies in the Mercedes blind spot sensor alignment are then addressed through precise adjustments, often requiring expertise in car body repair to ensure the sensors are perfectly aligned with the vehicle’s aerodynamic profile. The ultimate goal is to deliver a seamless driving experience while safeguarding drivers and surrounding traffic.

Mercedes blind spot sensor alignment is a critical component of overall vehicle safety. Utilizing Xentry diagnostics, professionals can accurately validate and calibrate these sensors, ensuring they function optimally. By adhering to rigorous testing procedures, drivers can experience enhanced peace of mind while navigating busy roads, knowing their Mercedes is equipped with top-tier blind spot detection technology.