Internal panel corrosion in vehicles requires proactive measures. By identifying and addressing causes like moisture intrusion, poor ventilation, and incorrect storage, owners can implement effective corrosion protection procedures. These include advanced paint repair, meticulous auto body work, and specialized corrosion inhibitors tailored to modern vehicle materials and environmental conditions. A comprehensive approach, combining preventive measures, regular maintenance, and prompt issue resolution, extends the lifespan of internal panel surfaces in luxury vehicles, preserving aesthetics and value.

Corrosion is a significant concern in various industries, especially internal panel corrosion within structures and equipment. This article explores essential techniques for protecting against this destructive force. We delve into understanding the causes of internal panel corrosion, selecting powerful corrosion inhibitors, and implementing effective strategies to ensure longevity. By employing these proven procedures, organizations can mitigate risks, extend asset lifespans, and maintain optimal performance in corrosive environments.

- Understanding Internal Panel Corrosion Causes

- Selection of Effective Corrosion Inhibitors

- Implementation Strategies for Longevity Assurance

Understanding Internal Panel Corrosion Causes

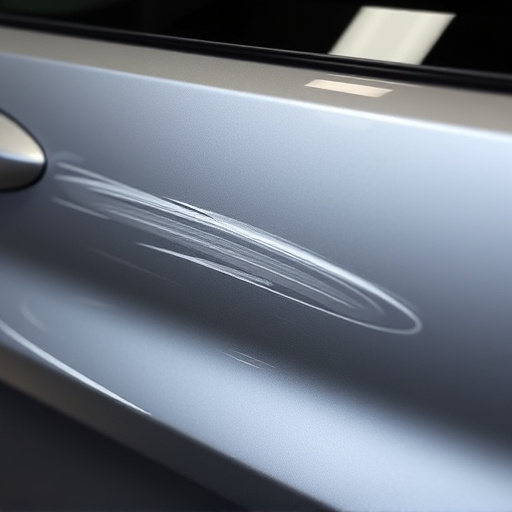

Internal panel corrosion in vehicles is a common issue that requires careful attention to prevent significant structural damage and ensure vehicle longevity. Understanding the causes is the first step in implementing effective corrosion protection procedures. This process often begins with identifying the primary factors contributing to corrosion, such as moisture intrusion, poor ventilation, or incorrect storage practices. For instance, water seepage through cracks or gaps can accelerate corrosion, especially in regions with harsh climates.

Automotive repair experts emphasize that preventing internal panel corrosion involves a multi-faceted approach. Vehicle paint repair techniques play a crucial role by creating a protective barrier against environmental elements. Proper auto body repairs, including sealing and coating, are essential to block moisture and prevent its interaction with metal surfaces. By combining these corrosion protection procedures, vehicle owners can maintain the integrity of their cars’ internal panels, ensuring better overall performance and reduced maintenance costs over time.

Selection of Effective Corrosion Inhibitors

When it comes to internal panel corrosion protection, selecting the right corrosion inhibitors is paramount. These additives play a crucial role in preventing the deterioration of automotive interiors, which are often exposed to moisture and other corrosive elements. In the context of car collision repair and Mercedes-Benz repair, where panels may have sustained damage or been temporarily removed, choosing effective corrosion inhibitors becomes even more critical.

The key lies in understanding the specific needs of different materials used in modern vehicles. For instance, polyolefins, commonly found in many interior components, require specialized inhibitors that can penetrate and react with these materials to form protective barriers. Moreover, considering environmental factors such as humidity levels and temperature fluctuations is essential when selecting corrosion protection procedures. By tailoring the inhibitor formula to these variables, you ensure longer-lasting protection for all types of collision damage repair scenarios, be it a simple dent removal or complex panel replacement.

Implementation Strategies for Longevity Assurance

Ensuring the longevity of internal panel surfaces is a key aspect of effective corrosion protection procedures. Implementation strategies should focus on preventive measures to create a robust defense against corrosive elements. Regular maintenance and inspection are essential; checking for signs of moisture intrusion, rust formation, or any structural weaknesses. Addressing these issues promptly can significantly extend the lifespan of vehicle bodywork, particularly in luxury vehicle repair scenarios where aesthetics and value retention are paramount.

Applying corrosion protection procedures involves utilizing specialized coatings and treatments designed to create a protective barrier. These include epoxy resin injections for sealing vulnerable joints and gaps, as well as underbody coatings that provide an extra layer of defense against road salt, acidic spills, and other environmental contaminants. Car paint services professionals should be adept at recommending and applying these treatments, tailoring them to the specific needs of different vehicle types and use cases.

Corrosion protection procedures for internal panels require a comprehensive approach, addressing cause, inhibitor selection, and long-term implementation strategies. By understanding the intricacies of internal panel corrosion causes, choosing the right corrosion inhibitors, and adopting effective implementation strategies, you can significantly extend the lifespan of your internal panels. These techniques not only enhance structural integrity but also contribute to cost savings and environmental sustainability in various industries.