OEM collision repair standards ensure vehicles are restored to manufacturer quality and safety through precise techniques, using OEM parts, and advanced technologies. Adhering to these guidelines provides consistent, efficient, and safe repairs, enhancing structural and visual appeal, ultimately leading to higher customer satisfaction. Robust quality control measures, including structured training, certified tools, regular inspections, and continuous monitoring of paint jobs, are crucial for meeting and maintaining these standards.

In the realm of automotive restoration, ensuring quality through Original Equipment Manufacturer (OEM) collision repair standards is paramount. This article delves into the significance of these standards and their multifaceted benefits for both repair shops and vehicle owners. We explore how adhering to OEM guidelines enhances structural integrity, preserves vehicle performance, and ensures a seamless return to the road. Additionally, we provide practical strategies for implementing and maintaining rigorous quality control measures, ultimately underscoring the importance of consistent collision repair excellence.

- Understanding OEM Collision Repair Standards

- Benefits of Adhering to These Standards

- Implementing and Maintaining Quality Control Measures

Understanding OEM Collision Repair Standards

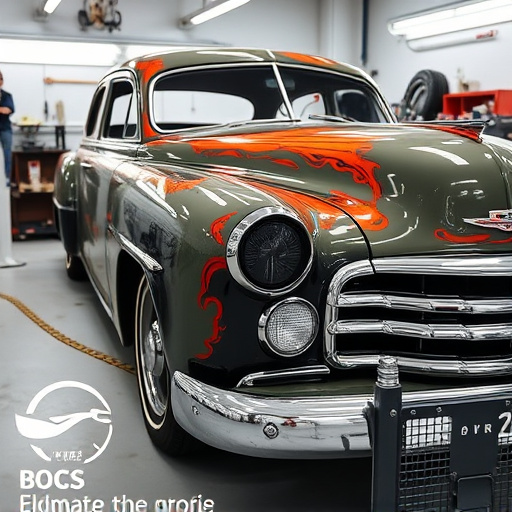

OEM Collision Repair Standards are a set of stringent guidelines designed to ensure that vehicle repairs maintain the original manufacturer’s quality and safety standards. These standards cover everything from material specifications to precise measurement techniques, guaranteeing that each part of the car is restored to its pre-accident condition or better. Understanding these standards is crucial for auto repair shops aiming to offer top-tier services, especially when it comes to scratch repair, bumper repair, and other intricate work.

By adhering to OEM guidelines, collision repair technicians can ensure the longevity and performance of repaired vehicles. This involves using original equipment parts (OEM), following manufacturer-recommended procedures, and employing advanced technologies to achieve precise outcomes. Whether it’s a minor dent removal or a complete panel replacement, mastering these standards is key for any reputable auto repair shop.

Benefits of Adhering to These Standards

Adhering to OEM (Original Equipment Manufacturer) collision repair standards brings numerous advantages for both repair shops and vehicle owners. These standards act as a blueprint, ensuring that repairs are carried out with precision and maintain the vehicle’s original integrity. One of the key benefits is consistency; following these guidelines guarantees that auto body work meets or exceeds the manufacturer’s specifications, resulting in a superior finish. This is particularly crucial for complex automotive restoration projects, where every detail matters to preserve the car’s historical value.

Furthermore, adhering to collision repair standards facilitates efficient and safe processes. It streamlines the repair process, ensuring that technicians follow proven methods, which reduces errors and potential secondary damage. In the event of auto glass replacement, for instance, these standards promote safety by dictating the use of high-quality materials and installation techniques, enhancing both structural integrity and visual appeal. Ultimately, embracing OEM collision repair standards contributes to a higher level of customer satisfaction, as vehicles are restored to their pre-accident condition or even beyond.

Implementing and Maintaining Quality Control Measures

Implementing and maintaining quality control measures is paramount in OEM collision repair standards. It involves a systematic approach to ensure that every step of the repair process adheres to the highest industry benchmarks. This starts with thorough training for technicians on the specific collision repair standards set by Original Equipment Manufacturers (OEMs). Proper tools, equipment, and materials certified for automotive use must be readily available to support this training.

Regular inspections and testing are essential components of quality control. These procedures validate that the car body repair meets OEM specifications, ensuring precision and accuracy in both structural integrity and cosmetic outcomes. Auto painting, a critical aspect often affected by collision damage, must also conform to OEM standards for color match and finish quality. Continuous monitoring and adjustments based on feedback guarantee that auto repair services maintain their level of excellence over time.

By adopting and strictly adhering to OEM collision repair standards, automotive professionals can ensure superior quality repairs that meet or exceed manufacturer specifications. This holistic approach, encompassing both understanding these standards and implementing robust quality control measures, not only safeguards vehicle integrity but also enhances customer satisfaction. In the competitive automotive industry, maintaining these high standards is a game-changer, fostering trust and ensuring long-lasting relationships with clients.