Model X crash repair requires a structured process from damage assessment to precise repairs using advanced tools and genuine or certified parts. Efficient management of parts availability through strategic supplier relationships is crucial for timely service, customer satisfaction, and maintaining vehicle integrity and performance. Prioritizing skilled technicians and high-quality components ensures safety, longevity, and peace of mind post-crash.

Model X crash repair is a specialized process that requires precise knowledge, advanced techniques, and efficient parts management. As electric vehicle technology continues to evolve, understanding the intricacies of Model X crash repair becomes crucial for ensuring safety and minimizing downtime. This article explores two key aspects: the crash repair process itself and managing parts availability to streamline repairs. By delving into these topics, we aim to help technicians and owners navigate the complexities of Model X crash restoration.

- Understanding Model X Crash Repair Process

- Managing Parts Availability for Efficient Repairs

- Ensuring Quality and Safety in Replacement Parts

Understanding Model X Crash Repair Process

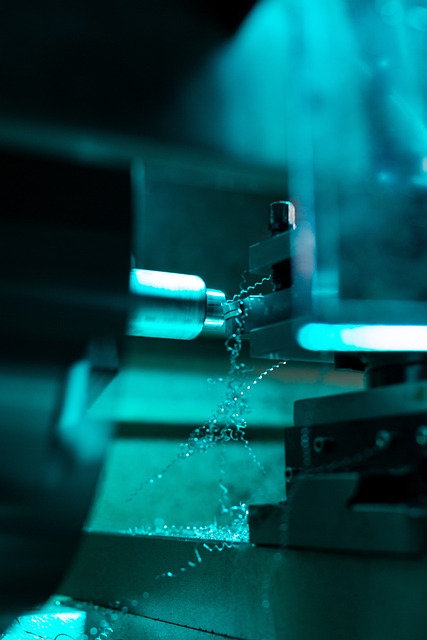

When a Model X vehicle is involved in an accident, the crash repair process involves several critical steps to ensure safety and quality restoration. It begins with a thorough inspection to assess the damage, which includes examining the car’s bodywork for dents, cracks, or any structural compromises. Skilled technicians use advanced tools and techniques to make precise repairs, restoring the vehicle to its pre-accident condition. The process may involve replacing damaged panels, realigning frames, and refining paintwork for a seamless finish.

Effective management of parts availability is a cornerstone of successful Model X crash repair. Collision repair shops need access to genuine or certified replacement parts that meet Tesla’s strict quality standards. Fleet repair services often prioritize streamlining this process through strategic partnerships with reliable suppliers, ensuring that the necessary components are readily available when needed. This prompt supply of authentic car bodywork parts contributes to efficient repairs and customer satisfaction.

Managing Parts Availability for Efficient Repairs

Managing parts availability is a critical aspect of efficient Model X crash repair. As with any automotive collision repair, having the right parts on hand ensures faster turnaround times and higher customer satisfaction. For Tesla models like the Model X, specialized parts are often required to maintain the vehicle’s unique design and performance features. Effective inventory management involves staying updated on parts supply chains, anticipating demand based on repair trends, and fostering strong relationships with reliable suppliers.

This proactive approach not only minimizes delays in tire services and vehicle body repair but also ensures that the repairs are carried out using genuine Tesla components, preserving the integrity of the Model X’s advanced technology and ensuring long-lasting performance. By streamlining parts availability, auto repair shops can better serve their customers and maintain a competitive edge in the market.

Ensuring Quality and Safety in Replacement Parts

When handling Model X crash repairs, prioritizing quality and safety in replacement parts is paramount. Using genuine or certified OEM (Original Equipment Manufacturer) parts ensures that your vehicle’s structural integrity and performance are restored to pre-accident conditions. These parts are designed specifically for the Model X, guaranteeing a seamless fit and reliable operation.

Moreover, choosing reputable sources for auto collision centers or fleet repair services can significantly impact the overall quality of repairs. Reputable providers offer high-quality replacement components, employ skilled technicians, and adhere to strict safety standards. This ensures not only the longevity of your vehicle but also your peace of mind on the road after a crash.

The efficient management of Model X crash repairs hinges on understanding the unique process, ensuring optimal parts availability, and prioritizing quality safety standards. By implementing strategic approaches to these key areas, repair shops can enhance customer satisfaction, minimize downtime, and maintain the integrity of each vehicle restored. Effective parts availability management, combined with a commitment to high-quality replacements, is vital for upholding the reputation of Model X vehicles as safe, reliable, and top-performing on the road.