Global structural safety standards like ISO 9001 are crucial for industries like automotive manufacturing and repair, ensuring product safety and international trade compliance. Stricter government regulations drive adoption of structural safety verification standards, requiring meticulous attention to detail during design and build phases. These standards enhance quality control, mitigate risks, and spur innovation, with collision centers investing in advanced technologies like CAD software and 3D scanning for accurate repairs and streamlined processes.

In today’s construction landscape, regulatory requirements are driving the adoption of stringent structural safety verification standards globally. As buildings become increasingly complex, ensuring structural integrity has never been more critical. This article delves into understanding international structural safety standards, exploring the regulatory pressures pushing their implementation. We analyze the profound impact on engineering and construction practices, highlighting how these standards foster safer, more resilient structures. By examining these trends, we uncover the future of structural safety verification.

- Understanding Global Structural Safety Standards

- Regulatory Pressure: Driving Forces Behind Adoption

- The Impact on Construction and Engineering Practices

Understanding Global Structural Safety Standards

Global structural safety standards play a pivotal role in ensuring the integrity and reliability of various industries, with a particular focus on the automotive sector. These standards are designed to safeguard individuals and property by mandating specific safety protocols and materials for construction and manufacturing processes. The International Organization for Standardization (ISO), for instance, has developed comprehensive guidelines for structural integrity, including ISO 9001 for quality management systems.

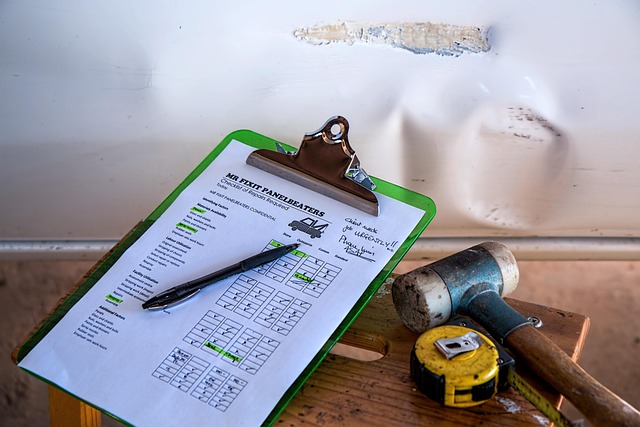

Understanding these global standards is crucial for businesses, especially automotive repair services and auto painting shops. Adherence to such regulations not only ensures product safety but also opens avenues for international trade. For an automotive body shop, implementing structural safety verification processes becomes essential when dealing with vehicle repairs and replacements, ensuring that every component meets the required safety criteria before final reassembly.

Regulatory Pressure: Driving Forces Behind Adoption

Regulatory pressure has emerged as a powerful force, propelling the adoption of structural safety verification standards across various industries. With an increasing focus on ensuring safety and quality, governments worldwide are implementing stringent regulations that demand higher levels of scrutiny and compliance for products and services. In the context of the automotive sector, this translates into stricter guidelines for car repair shops, auto collision centers, and collision repair centers to follow when dealing with vehicle structural integrity.

This shift is driven by several key factors. Firstly, the rise in complex vehicle designs necessitates advanced verification methods to assess structural safety. Secondly, the desire to prevent accidents and reduce the impact of collisions has led to more rigorous testing and certification processes. As a result, collision repair centers are being compelled to adapt and embrace standardized safety protocols, thereby fostering a culture of quality and reliability within the industry.

The Impact on Construction and Engineering Practices

The implementation of structural safety verification standards has had a profound impact on construction and engineering practices. These stringent regulations demand meticulous attention to detail during the design and build phases, ensuring that every aspect of a structure meets stringent safety criteria. This shift has led to more rigorous quality control measures, as professionals must adhere to specific guidelines and employ advanced technologies for precise analysis and verification. The result is enhanced structural integrity, reducing risks associated with potential failures or hazards.

Moreover, the adoption of these standards has prompted innovative solutions in the automotive industry, closely tied to vehicle collision repair and car scratch repair services. As safety regulations tighten, collision centers and body shops are investing in advanced equipment capable of performing intricate structural safety verifications, including computer-aided design (CAD) software and 3D scanning technology. This not only facilitates accurate repairs but also streamlines the process, ensuring that vehicles meet safety standards after accidents, be it minor fender benders or more severe collisions.

Global regulatory requirements are significantly driving the adoption of structural safety verification standards, reflecting a growing emphasis on ensuring safe and resilient built environments. As these standards gain traction, construction and engineering practices stand to benefit from enhanced safety protocols, improved project quality, and increased public confidence. The integration of structural safety verification becomes not just a compliance necessity but a cornerstone for progress in the industry, paving the way for more innovative and secure infrastructure projects worldwide.