DTC clearing after repair is a meticulous process ensuring luxury car repairs return to pre-damage condition. Technicians use specialized tools like dent removal equipment and air compressors for accurate paint removal, adhering to strict quality standards to guarantee customer satisfaction and precise outcomes in collision repair scenarios.

In the realm of technical precision, the DTC (Direct-to-Consumer) clearing process is a critical step post repair. This article delves into the intricate details of navigating this procedure, specifically focusing on the essential tools that technicians utilize for accurate and seamless DTC clearing. From understanding the foundational steps to adopting best practices, we explore strategies to ensure a smooth transition from repair to consumer delivery, highlighting the significance of efficient DTC clearing after repair.

- Understanding DTC Clearing Process

- Essential Tools for Accurate Clearing

- Best Practices for Seamless Post-Repair Clearing

Understanding DTC Clearing Process

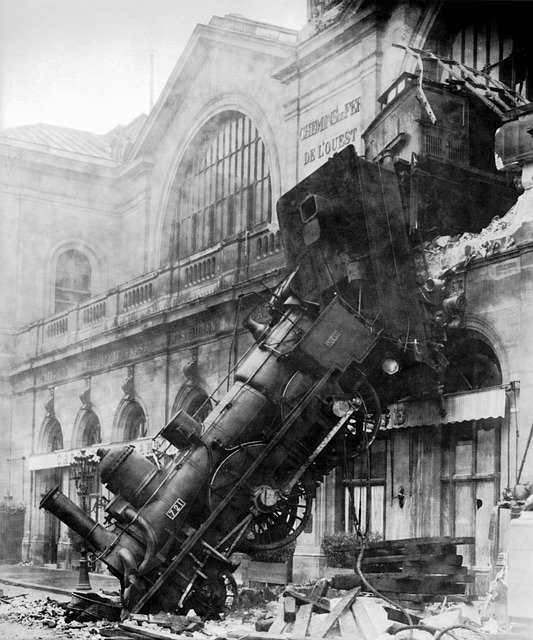

The DTC (Direct to Consumer) clearing process after a car repair is a critical step that ensures the vehicle’s return to its pre-damage condition. It involves removing any remnants of damage, such as dents or scratches, without the need for extensive paintwork. This method is particularly popular in Mercedes Benz repairs and other car damage repair scenarios where preserving the vehicle’s original finish is paramount.

Technicians utilise a range of tools and techniques for this delicate process, including specialized dent removal equipment for paintless dent repair. These tools allow for precise manipulation of the metal without compromising the factory finish. Accurate DTC clearing demands a deep understanding of materials science, as technicians must carefully match the original panel’s texture, colour, and gloss to ensure a seamless blend that hides all evidence of previous damage, be it from minor fender benders or more significant accidents.

Essential Tools for Accurate Clearing

In the realm of automotive restoration, especially after a car collision repair or vehicle paint job (auto painting), accurate DTC (Direct to Car) clearing is paramount. Technicians armed with the right tools ensure that all paints, primers, and adhesives are thoroughly removed, leaving no remnants behind. This meticulous process not only prepares the vehicle for its final stage but also guarantees a flawless finish, aligning perfectly with the aesthetics of modern auto painting and vehicle repair services.

The toolkit for precise DTC clearing is a symphony of specialized equipment. It includes powerful yet controlled strippers to dissolve tough adhesives, precision scrapers for removing stubborn residue, and high-pressure washers to thoroughly clean hard-to-reach areas. Additionally, air compressors play a vital role in drying surfaces quickly post-clearing, preventing any moisture-related issues that could mar the final product, particularly in car collision repair scenarios where precision is key.

Best Practices for Seamless Post-Repair Clearing

Maintaining a meticulous DTC (Direct to Consumer) clearing process after repairs is paramount for technicians to ensure customer satisfaction and accurate results. Best practices involve adhering to strict quality standards throughout, using specialized tools designed for precision, and meticulously documenting each step of the clearing procedure. This includes thorough inspections to identify any remaining debris or imperfections from the repair site before applying the final clear coat.

Technicians should also prioritize proper ventilation in the auto painting or car restoration environment to prevent the build-up of harmful fumes, ensuring both worker safety and the integrity of the finishing process. Additionally, utilizing advanced equipment like air pressure washers and fine-toothed scrapers can effectively remove surface impurities without damaging freshly repaired surfaces, contributing to a seamless post-repair DTC clearing experience in an automotive body shop.

The efficient DTC clearing process after repairs relies on a combination of specialized tools and best practices. By understanding the intricate steps involved, technicians can ensure accurate data transfer and seamless post-repair operations. Adopting essential tools tailored for this purpose not only streamlines the workflow but also enhances overall system integrity. Following established best practices further mitigates errors, resulting in a robust DTC clearing process that keeps systems updated and functioning optimally.