A repair quality inspection ensures vehicle repairs meet high standards critical for safety and customer satisfaction. It involves verifying work against manufacturer guidelines and legal requirements through structural integrity, paint quality, and alignment precision checks. Skilled technicians conduct meticulous visual assessments, document each step, and provide detailed reports to guarantee a flawless, safe, and durable vehicle after any repair or restoration.

A thorough repair quality inspection is paramount in ensuring structural integrity and safety. This comprehensive guide delves into the key components that define a successful inspection process. From understanding industry standards to performing meticulous visual assessments, each step plays a vital role in maintaining high-quality repairs. Learn how detailed documentation and insightful reporting contribute to accountability, ultimately fostering trust among stakeholders. Discover the essential items checked in every repair quality inspection to guarantee superior outcomes.

- Understanding Repair Quality Inspection Standards

- Essential Components of Visual Assessment

- Documentation and Reporting for Accountability

Understanding Repair Quality Inspection Standards

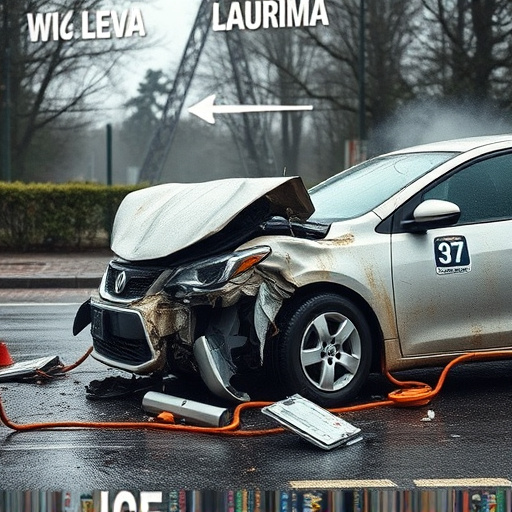

A repair quality inspection is a meticulous process designed to ensure that vehicle repairs meet the highest standards. These inspections are crucial for maintaining safety and customer satisfaction in the automotive industry, especially after collision damage repair or other body shop services. The primary objective is to verify the accuracy and effectiveness of the repair work, ensuring it adheres to both manufacturer guidelines and legal requirements.

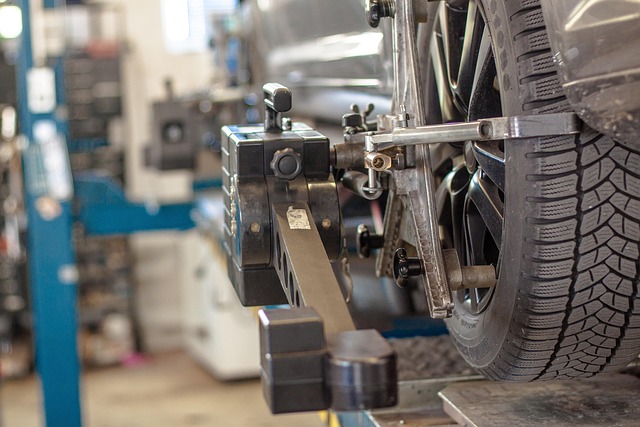

Proper inspection procedures involve a thorough review of various aspects, including structural integrity, paint quality, and alignment precision. Technicians must possess extensive knowledge of vehicle construction and repair techniques to identify even subtle issues. By adhering to these rigorous standards, body shops can guarantee that vehicles are restored to their pre-incident condition, providing peace of mind for customers who rely on reliable transportation.

Essential Components of Visual Assessment

During a repair quality inspection, the visual assessment is a crucial step that involves meticulous examination of various components. Skilled technicians pay close attention to details, as even the tiniest discrepancies can impact the overall repair’s success. The initial visual scan helps identify visible damage, such as dents, cracks, or scratches, which are common in luxury vehicle repairs and automotive restoration processes.

This preliminary inspection also involves checking the paint job for consistency, gloss, and color accuracy. Technicians look for signs of improper patching, misaligned body panels, or unevenness in the finish, ensuring a flawless appearance. Moreover, the assessment includes evaluating the integrity of seals, gaskets, and other structural elements to guarantee the vehicle’s overall safety and durability after repair, be it a simple scratch repair or a comprehensive automotive restoration project.

Documentation and Reporting for Accountability

In a repair quality inspection, proper documentation and reporting are vital for maintaining accountability. Skilled technicians meticulously document every step taken during the repair process, including parts replaced, work performed, and time taken. This detailed record-keeping ensures transparency and serves as a reference point for future maintenance or repairs. Accurate reports not only facilitate internal tracking but also foster trust with clients, especially in an auto collision center or collision repair center.

Effective documentation enables seamless communication between the shop and its customers. When a client brings their vehicle to a car dent repair facility, they receive a comprehensive report outlining the initial damage assessment, the repairs conducted, and the final results. This not only keeps the client informed but also acts as a permanent record, ensuring that both parties are on the same page regarding the quality of work done in the collision repair center.

A comprehensive repair quality inspection is vital for ensuring that repairs are carried out to a high standard. By adhering to established inspection standards, visually assessing key components, and maintaining thorough documentation, professionals can guarantee customer satisfaction and the longevity of repaired items. These practices form the backbone of any successful repair service, emphasizing the importance of meticulous attention to detail during every step of the process.