Resistance spot welding is a sophisticated, precise method for vehicle repair, especially frame straightening. It uses specialized equipment to melt and fuse metal with controlled temperature, pressure, and time, minimizing heat impact and damage to surrounding areas. This technique offers swift repair times, guarantees structural integrity, and is ideal for complex car damage, making it an indispensable tool in top-tier auto collision centers.

Resistance spot welding is a critical process in vehicle repairs, offering precision and strength. This advanced technique has transformed auto restoration, enabling efficient joining of metal components. In this article, we’ll explore the intricacies of resistance spot welding, its benefits for vehicle repair, and the step-by-step process behind this game-changing technology. Discover how it ensures indelible bonds, enhancing safety and performance in today’s automotive landscape.

- Understanding Resistance Spot Welding Techniques

- Advantages in Vehicle Repair and Restoration

- The Process: From Start to Finish

Understanding Resistance Spot Welding Techniques

Resistance spot welding is a precise and effective technique used extensively in vehicle repairs, particularly for joining metal components within an auto collision center or frame straightening operations. This method involves the use of a resistance welder to melt a small portion of the overlapping metals, creating a strong bond. The process is highly controlled, allowing for accurate adjustments to temperature, pressure, and time, ensuring optimal weld quality.

This advanced welding technique plays a crucial role in modern collision repair centers, enabling efficient frame repairs and structural integrity restoration. By focusing on specific points of contact, resistance spot welding minimizes heat input to surrounding areas, preserving the overall integrity of the vehicle’s body while facilitating swift and durable repairs.

Advantages in Vehicle Repair and Restoration

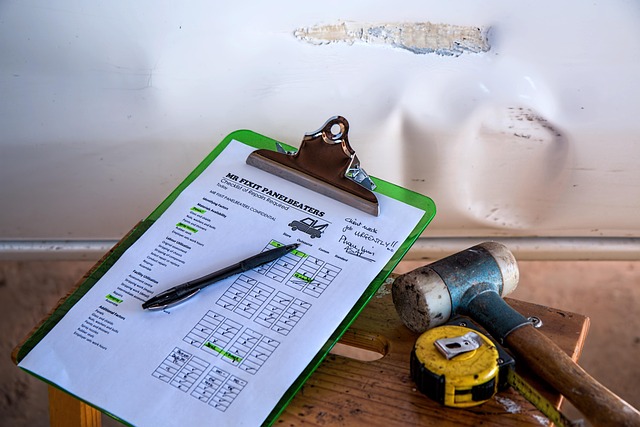

Resistance spot welding offers several advantages when it comes to vehicle repair and restoration. This precise technique allows for strong and durable bonds, making it ideal for fixing or replacing damaged panels, such as those affected by a fender bender. It’s particularly beneficial in collision repair shops where speed, strength, and efficiency are paramount.

Compared to traditional welding methods, resistance spot welding is less invasive, resulting in minimal heat input and reduced risk of damaging surrounding materials or altering the original car paint repair. This subtlety ensures that vehicles can be restored to their pre-accident condition, maintaining their aesthetic appeal and structural integrity.

The Process: From Start to Finish

Resistance spot welding is a precise and powerful technique that plays a pivotal role in modern vehicle repairs. The process begins with preparing the metal surfaces to be joined, ensuring they are clean and free from contaminants. A welder then positions two metal plates precisely, aligning them perfectly for the next step. An electric current is applied, creating a concentrated heat source at a specific point between the plates, which melts the metal, forming a weld.

As the heat intensifies, the weld pool forms, and the metal fuses together, resulting in a strong bond. The welder controls the time, current, and pressure to ensure a consistent and high-quality weld. Once complete, the excess material is removed, leaving a clean, durable joint. This method is highly effective for repairing car damage repair, especially in complex cases where precision is key, making it an indispensable tool in any reputable car repair shop offering top-notch vehicle repair services.

Resistance spot welding has emerged as a pivotal technique in the vehicle repair and restoration industry, offering numerous advantages over traditional joining methods. By understanding its techniques and appreciating the process, professionals can ensure robust, efficient, and precise repairs. This specialized welding method not only enhances structural integrity but also contributes to lighter vehicle builds, thereby improving fuel efficiency. As resistance spot welding continues to gain traction, its role in shaping the future of automotive maintenance and restoration is undeniable.