Structural integrity restoration costs are rising due to material and labor shortages, global supply chain disruptions, and skilled labor scarcity. By 2025, advanced technology like CAD software and robotic systems will enhance precision and efficiency, while eco-friendly materials and sustainable practices will improve quality and durability. Despite increased costs, competition and consumer demand for quality could mitigate rises, making structural integrity restoration more accessible and advanced than ever.

In 2025, the landscape of structural integrity restoration is undergoing a significant shift as costs continue to rise. This article delves into the driving factors behind this trend, focusing on two key areas: the increasing expenses of materials and labor, and the integration of advanced technology in restoration efforts. We also explore future trends and attempt to predict manageable cost paths for industry professionals and property owners alike, emphasizing the importance of proactive maintenance and innovative solutions in ensuring structural integrity.

- Rising Costs of Materials and Labor

- Advanced Technology's Role in Restoration

- Future Trends and Predictable Costs

Rising Costs of Materials and Labor

In recent years, the cost of structural integrity restoration has been on a steady upward trend, with 2025 marking another significant jump. This surge can primarily be attributed to the rising expenses of both materials and labor in the construction and repair sectors. The global shortage of essential building materials, exacerbated by supply chain disruptions, has led to price increases across the board. Steel, a fundamental component in many restoration projects, is particularly affected due to its high demand in various industries.

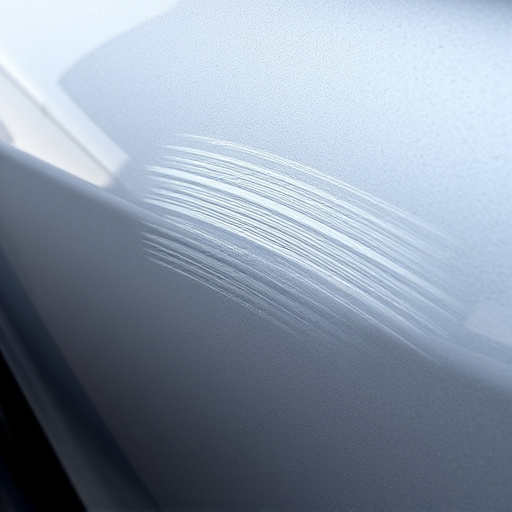

Moreover, the skilled labor pool responsible for executing these complex repairs is facing its own challenges. The automotive collision repair and dent removal sectors, often crucial components of structural integrity restoration, are grappling with labor shortages. This has resulted in increased wages as businesses compete to attract and retain highly skilled workers. As a ripple effect, these higher labor costs contribute to the overall rise in restoration expenses, making it an important factor for property owners and businesses alike to consider when planning for future repairs.

Advanced Technology's Role in Restoration

The year 2025 is poised to witness a significant shift in the landscape of structural integrity restoration due to advanced technology. Modern tools and methods are revolutionizing the way we approach repairs, ensuring precision and efficiency. From computer-aided design (CAD) software that aids in complex measurements and planning to robotic systems that can handle intricate tasks, these innovations are reducing human error and speeding up the entire restoration process.

Imagine a scenario where a car involved in a fender bender or collision requires meticulous structural integrity restoration. Advanced technology streamlines this process, enabling experts to offer precise mercedes benz repair solutions. Collision repair services are no longer just about fixing dents; they involve intricate adjustments to ensure the vehicle’s overall structural soundness. This level of precision not only enhances safety but also ensures that restored vehicles meet the highest standards, making them virtually indistinguishable from their original state.

Future Trends and Predictable Costs

As we look ahead to 2025, several future trends are set to impact the structural integrity restoration industry. Advancements in technology, such as improved diagnostic tools and precision engineering techniques, will play a significant role in enhancing restoration accuracy and efficiency. The rise of eco-friendly materials and sustainable practices is also expected to shape the market, aligning with global efforts towards environmental conservation. These innovations are likely to drive up costs for classic car restoration and other specialized services, but they promise higher quality outcomes and longer-lasting repairs.

Predictable cost increases in structural integrity restoration will be driven by several factors. Labor shortages and a growing demand for skilled technicians will push wages higher. Additionally, the rising cost of raw materials and advanced technologies used in auto body repairs and vehicle collision repair will contribute to overall price inflation. However, increased competition among restoration specialists and a consumer preference for quality over quick fixes could mitigate these costs to some extent. Ultimately, while classic car restoration enthusiasts may face slightly higher expenses, the industry’s evolution suggests a future where structural integrity restoration is both more accessible and more advanced than ever before.

As we look ahead to 2025, the structural integrity restoration industry faces a landscape shaped by rising costs. From materials and labor to technological advancements, these factors are driving change in how we approach structural repairs. By embracing innovative solutions and predicting cost trends, professionals can ensure sustainable pricing for services while maintaining high standards of quality. This proactive approach will be key to navigating the evolving demands of structural integrity restoration.