Using low-quality or improperly fitted auto body shop parts can lead to severe vehicle performance issues, handling problems, reduced gas mileage, and compromised safety, especially around crash sites. Incompatible parts often stem from human error, misjudgments, or the use of generic/aftermarket parts not meeting OEM standards, particularly in complex repairs. To ensure accuracy, auto body shops should implement rigorous quality control measures, maintain updated genuine or certified part inventories, and regularly train their staff on vehicle models and repair techniques, resulting in satisfied customers through efficient auto maintenance and superior dent repair outcomes.

In the realm of auto repair, ensuring that replacement parts fit perfectly is paramount. When auto body shop parts don’t align correctly, it can lead to significant issues affecting vehicle performance and safety. This article delves into the consequences, exploring common reasons behind improper fits and offering solutions for auto body shops to uphold standards. By implementing best practices, shops can guarantee customer satisfaction and maintain their reputation in a competitive market, ensuring every part seamlessly contributes to a vehicle’s optimal function.

- The Impact of Improperly Fitting Parts on Vehicle Performance

- Common Reasons for Incompatible Auto Body Shop Parts

- Solutions and Best Practices to Ensure Proper Fitting Parts in Auto Body Shops

The Impact of Improperly Fitting Parts on Vehicle Performance

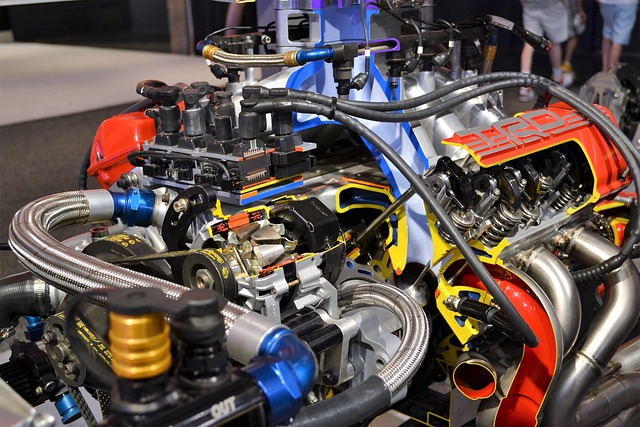

When auto body shop parts don’t fit properly, it can have a significant impact on a vehicle’s overall performance and handling. Inaccurate or subpar replacements may lead to misalignment issues, causing the car to pull to one side during driving, affecting stability and safety. Moreover, poorly fitted parts can result in reduced gas mileage due to air leaks or improper sealing, leading to increased fuel consumption.

Improperly installed components might also compromise the vehicle’s structural integrity, particularly around the crash sites where reinforcement is crucial for safety. This can negatively influence how the car absorbs and distributes impact energy during future collisions, potentially rendering the collision repair services less effective and increasing the risk of secondary damage. As such, ensuring that only high-quality auto body shop parts fit properly is paramount for maintaining optimal vehicle performance and passenger safety after a car damage repair.

Common Reasons for Incompatible Auto Body Shop Parts

Incompatible auto body shop parts can arise from a variety of reasons. One of the most common is human error during installation. Despite meticulous measurements and calculations, misjudgments or misinterpretations of specifications can lead to parts that simply don’t fit properly. This is especially true in complex repair jobs involving vehicle dent repair or intricate vehicle restoration processes, where precise fitting is crucial for structural integrity and aesthetic harmony.

Another significant factor is the use of generic or aftermarket auto body shop parts instead of OEM (Original Equipment Manufacturer) parts. While cost-effective, these replacement parts may not be manufactured to the exact dimensions and specifications of the original components, resulting in fitment issues. Auto detailing professionals often face this challenge, as customers seek affordable solutions that might not align with the meticulous standards required for a seamless finish.

Solutions and Best Practices to Ensure Proper Fitting Parts in Auto Body Shops

Proper fitting auto body shop parts are crucial for ensuring a seamless vehicle repair and restoration process. If parts don’t align correctly, it can lead to unsightly gaps or misalignments, compromising both the cosmetic appeal and structural integrity of the vehicle. To mitigate this, auto body shops should prioritize quality control measures. This includes meticulous part inspection upon arrival, verifying compatibility with the specific make and model of the vehicle, and cross-referencing against detailed specifications.

Best practices also involve utilizing specialized tools for precise measurements and adjustments before installation. Trained technicians play a pivotal role in ensuring each component fits securely and accurately. Additionally, keeping an up-to-date inventory of genuine or certified replacement parts can help avoid compatibility issues. Regular staff training on the latest vehicle models and repair techniques further reinforces the accuracy of part fitting, ultimately contributing to customer satisfaction through efficient auto maintenance and superior auto dent repair outcomes.

When auto body shop parts don’t fit properly, it can significantly impact vehicle performance and safety. Incompatibility issues often arise due to variations in manufacturing standards or using the wrong specifications. To mitigate these problems, auto body shops should adopt best practices such as meticulous measurement, adherence to industry standards, and utilizing high-quality, compatible parts. Regular training for staff and staying updated with manufacturer guidelines can also ensure that the right parts are fitted correctly, enhancing vehicle reliability and customer satisfaction.