Hybrid and electric vehicle (HEV) collision repairs pose unique challenges due to intricate electrical systems and specialized components, requiring skilled technicians and prolonged wait times. Delays in acquiring parts are a significant concern, as standard supply chains often fail to cater to HEVs' specific needs. However, digital era innovations like advanced training and tools enable faster, safer repairs, minimizing downtime for EV owners by addressing delay concerns in collision repair services.

In the realm of automotive repair, delay concerns collision particularly impact hybrid and electric vehicles (HEVs). These unique challenges stem from the intricate systems and specialized parts required for HEV repairs. This article delves into the specific hurdles faced in collision repair for HEVs, exploring delays in parts acquisition and their ripple effects on service times. Furthermore, it highlights innovative solutions that streamline the process, ensuring efficient and effective collision repair without compromising quality.

- Unique Challenges of Hybrid and Electric Vehicle Repairs

- Delays in Parts Acquisition and Their Impact

- Innovative Solutions for Efficient Collision Repair

Unique Challenges of Hybrid and Electric Vehicle Repairs

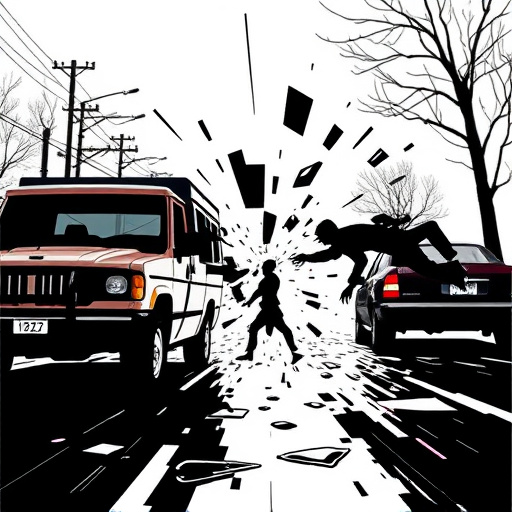

Hybrid and electric vehicles (EVs) present unique challenges when it comes to collision repairs compared to their traditional gasoline counterparts. One of the primary delay concerns is the intricate electrical systems and high-voltage components found in these modern vehicles. A simple fender bender can transform into a complex repair process, as auto repair technicians need specialized knowledge and equipment to safely address damage without causing short circuits or other electrical malfunctions.

Additionally, the integration of advanced driver-assistance systems (ADAS) and autonomous features further complicates repairs. These systems require precise recalibration and reprogramming to ensure they function correctly after a collision. Finding qualified technicians with expertise in EV repair near you can be challenging, leading to longer wait times as specialized auto repair shops may be necessary for comprehensive and safe restoration of these innovative vehicles.

Delays in Parts Acquisition and Their Impact

Delays in acquiring replacement parts can significantly impact collision repairs for hybrid and electric vehicles (HEVs). Unlike conventional cars, HEVs often require specialized components that may not be readily available or easily accessible through standard supply chains. This delay in parts acquisition can slow down the repair process, leading to longer wait times for vehicle owners.

For instance, a fender bender on a Mercedes-Benz repair might involve complex systems such as electric motors and battery packs. If these parts are not in stock or take longer to ship, it could result in extended downtime for the vehicle. Efficient inventory management and strong relationships with specialized suppliers become crucial in minimizing these delays, ensuring prompt and effective collision repairs for HEVs.

Innovative Solutions for Efficient Collision Repair

In today’s digital era, the delay concerns surrounding collision repair for hybrid and electric vehicles (EVs) have spurred innovation in auto body repairs. Traditional methods often face unique challenges due to the complex electrical systems and lightweight materials used in EVs. However, advanced training programs and specialized tools are now available to bridge this gap. Technicians are equipped with knowledge on how to safely disconnect high-voltage batteries, navigate intricate wiring harnesses, and perform precise auto body damage repair without compromising safety or functionality.

These innovative solutions not only ensure efficient collision damage repair but also expedite the overall restoration process. By adopting cutting-edge techniques, repair facilities can minimize downtime for EV owners, address delay concerns head-on, and ultimately provide top-notch services tailored to these specialized vehicles.

The delays associated with collision repair for hybrid and electric vehicles (HEVs) pose significant challenges, impacting both shop efficiency and customer satisfaction. By understanding the unique aspects of HEV repairs, such as specialized training, specific tools, and specialized parts, shops can effectively navigate acquisition delays. Embracing innovative solutions like modular repairs, streamlined communication, and advanced diagnostic tools can significantly reduce downtime, ensuring swift and reliable collision repair for these modern vehicles without compromising safety or quality.