Repair priority scheduling optimizes vehicle maintenance for commercial fleets by ranking repairs based on urgency, complexity, and functionality impact, minimizing downtime for critical vehicles, enhancing operational efficiency, and customer satisfaction. Integrating robust systems or specialized services ensures skilled technicians and parts are allocated timely for routine and unforeseen damages, while strategic methods like fleet assessments, predictive maintenance, and real-time monitoring prevent major breakdowns and boost brand value.

In the dynamic world of commercial and fleet vehicle management, efficient repair priority scheduling is paramount. This article delves into the essentials of understanding repair priority scheduling basics, highlighting key factors for effective fleet management. We explore practical strategies for implementing efficient commercial vehicle repairs, empowering professionals to optimize their maintenance processes. By mastering these techniques, organizations can minimize downtime, enhance operational productivity, and ultimately, stay competitive in today’s market. Discover how repair priority scheduling can revolutionize your fleet management approach.

- Understanding Repair Priority Scheduling Basics

- Factors to Consider for Effective Fleet Management

- Implementing Strategies for Efficient Commercial Vehicle Repairs

Understanding Repair Priority Scheduling Basics

Repair priority scheduling is a crucial system for efficiently managing vehicle repairs, especially in commercial and fleet operations where time and cost are significant factors. At its core, it involves determining the order in which repairs are performed based on their urgency, complexity, and impact on vehicle functionality. This basic concept ensures that critical issues are addressed promptly, minimizing downtime for essential vehicles like trucks or delivery vans.

By implementing repair priority scheduling, fleet managers can optimize their maintenance processes. For instance, prioritizing a quick fix like a simple car dent repair over less urgent but more complex tasks such as bumper repairs can significantly reduce overall turnaround time. This approach allows businesses to maintain high operational efficiency and customer satisfaction levels by keeping their vehicles on the road for longer periods.

Factors to Consider for Effective Fleet Management

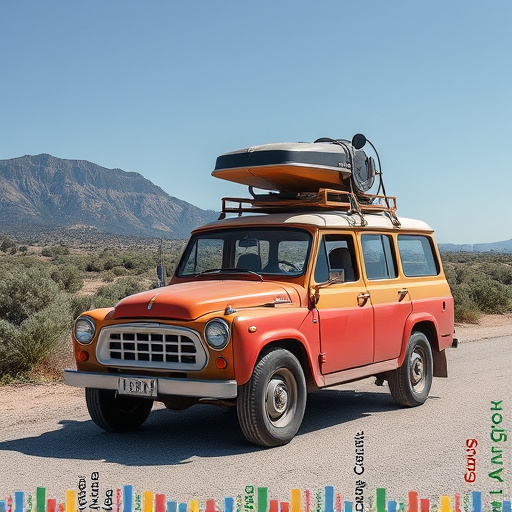

Effective fleet management involves a strategic approach to maintain vehicles in optimal condition, minimising downtime and costs. Successful scheduling of repairs is pivotal here, especially for commercial and fleet vehicle operations where efficiency and safety are paramount. Key factors to consider include the complexity of repairs, parts availability, and the impact on business operations.

Prioritising repairs based on urgency and severity ensures that vehicles are roadworthy and operational, preventing costly breakdowns. Integrating a robust repair priority scheduling system, such as those offered by auto body shops or specialised fleet management software, can streamline this process. This allows for efficient allocation of resources, including skilled technicians and parts, ensuring timely service for all vehicles in the fleet, whether it’s regular maintenance or unforeseen damages requiring auto repair services.

Implementing Strategies for Efficient Commercial Vehicle Repairs

In the dynamic world of commercial and fleet vehicle management, efficient repairs are paramount to maintaining operational efficiency. Implementing robust repair priority scheduling strategies is a game-changer, ensuring that vehicles are back on the road promptly. This involves prioritizing critical repairs based on severity, impact on operations, and potential safety hazards. By streamlining the repair process, businesses can minimize downtime, reduce costs, and enhance customer satisfaction.

A structured approach to repair priority scheduling includes regular fleet assessments, predictive maintenance strategies, and real-time monitoring of vehicle conditions. For instance, proactively addressing minor issues like a car dent repair or routine auto maintenance can prevent more significant breakdowns later. Similarly, focusing on specialized services like car paint repair for visible damage enhances the overall aesthetics and market value of the vehicles, contributing to a positive brand image.

Repair priority scheduling is a pivotal strategy for efficiently managing commercial and fleet vehicle repairs. By understanding the basics, considering key factors, and implementing effective strategies, businesses can significantly enhance their operational effectiveness and reduce downtime. Embracing repair priority scheduling allows for optimized resource allocation, faster turnaround times, and improved overall fleet management, ultimately contributing to enhanced productivity and cost savings.